Dougcole

Guru

Hi All,

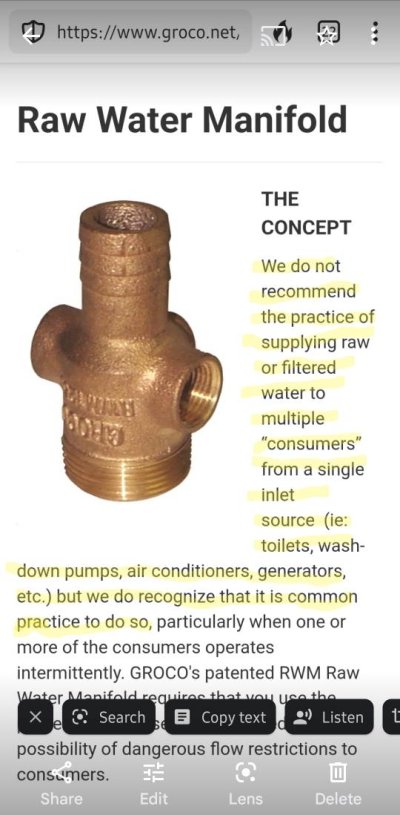

I am planning on doing a semi-permanent installation of our AC powered Rainmaker portable watermaker in our lazzerette which will require a pickup at a through hull. The generator is also in the laz, with a through hull and strainer in a perfect spot for the watermaker install. The genset is an 8K Kohler. The through hull is a 3/4" with a 3/4" hose feeding the gen-set.

I'd like to avoid installing another through hull if possible as it involves hauling the boat and added expense.

Do you think the watermaker can share a through hull with the gen-set? Both would be running at the same time.

Thanks

I am planning on doing a semi-permanent installation of our AC powered Rainmaker portable watermaker in our lazzerette which will require a pickup at a through hull. The generator is also in the laz, with a through hull and strainer in a perfect spot for the watermaker install. The genset is an 8K Kohler. The through hull is a 3/4" with a 3/4" hose feeding the gen-set.

I'd like to avoid installing another through hull if possible as it involves hauling the boat and added expense.

Do you think the watermaker can share a through hull with the gen-set? Both would be running at the same time.

Thanks