Capt. Dave Forsman, Pilgrim 40 "LIBERTY", Hull number 43 had a conversation with Mike Gozzard (35 minutes, 12/21/2010)

I originally called Gozzard with two requests. One thing led to another and we discussed quite a range of Pilgrim related items. Some of these items might be of interest to other Pilgrim owners so I transcribed the conversation, as I took notes while we were talking. Thanks to Mike for taking the time out his day to talk to me.

3) While removing a few unused though hull fittings I found the hull to be balsa cored, which surprised me as everything I read said the hulls were solid glass. When we did our purchase survey, I didn’t use a moisture meter on the bottom (wouldn’t work anyway due to the hard, copper based bottom paint), but rather used a hammer to do percussion sounding. We never found any suspect areas in the hull although the rudder and select areas of the deck were another story. When I mentioned to Mike that I wasn’t expecting to find the balsa core, he told me that as far as he knew that every Pilgrim built had ½” core that started about a foot from the turn of the bilge above the keel and ran up to the rub rail.

This led into a discussion of wet core and what to do regarding moisture readings. Evidently Gozzard (probably like most builders) has gotten a lot experience in recent years in fixing damp/wet/rotten core.

Assuming you are using a Skipper Moister Meter, this will read 11% on new, out of the box, core from Baltec. Less than 12% is obviously ok (perfect), 14% to 17% is marginal and anything over 20% needs repair. When repairing core, Mike suggested cutting the area open then using a probe type meter on the actual core. Any core that is 16% or over should be replaced, less than that and there is no point in removing that core as it is essentially fine.

My experiences last fall followed along those lines. We had an area just aft of the step on the starboard side deck that was soft. It metered wet, and when percussion tested, sounded dead, dead, dead. Since the previous owner of LIBERTY had recently replaced all the tankage in the so-called basement, all the tanks were new and one of them never had the installation finished.

Fortunately that was the tank under the wet deck allowing us relatively easy access to that region. Since we had the access, I decided to do the repair work from underneath the deck, more for the cultural experience than anything else. It would also allow us to use the boat while I was fooling with this repair. I marked off an area that was about 4’ in length by the entire width of the deck. I thought that since I was doing this it made sense to cut out anything that metered damp. The worst area was at the deck fill for the old water tank. It didn’t appear there was any bedding compound around that fill and it had been leaking for a long time.

The core was black and totally rotten in this area. The underside of the decking peeled right off in this region. As we got further from the rotten area and into the damp areas, the deck got harder and harder to remove. I wanted the glass to come off in one piece as I was going to re-use it so I was driving a small, long handled slick (big chisel) between the glass and the core.

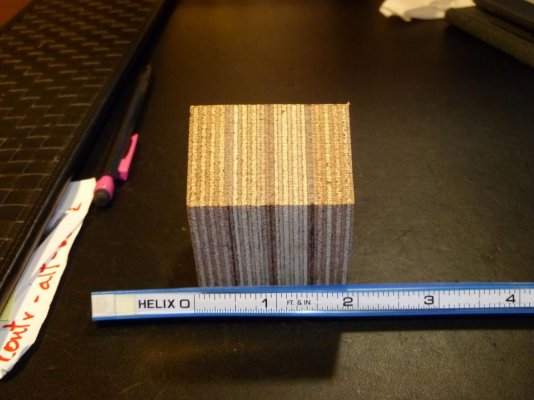

Since I made a perimeter cut to start, I was committed to taking off the entire piece. After much effort I did succeed but found that damp core to be structurally sound; in other words I over did the removal. For those that are interested, the top skin of the deck is about ¼” thick as is the bottom skin. The core is ½”. The boat deck core is 1” thick, at least above the pilot house.

There are real good reasons for using modern vacuum bagging when building composite structures as a lot of boat builders are now doing. Laying up glass/balsa structures in the traditional way can result in a resin starved area at the transition region between the glass and end grain balsa due to inadequate clamping pressure during lamination. If water gets in, it can wick its way down the structure, wetting the balsa from the top or bottom, but not from the side. This is what I found on the underside of our deck. A slight gap between the underside of the deck where the balsa was not firmly attached allowed the migration of the water and making a bad situation worse.

As a side note, where outboard scoop strainers were attached over the inlets on the through hulls, these areas metered damp, some as high as 16%, right around the through hull. What I found was the strainers were screwed into the hull with the screws piercing the core, no potting around the fasteners. This of course allowed moisture access to the core. After pulling the through hull and leaving it open to the air over the winter, the maximum moisture content dropped to 15%. This area was filled in with solid glass and epoxy, and regions that will receive fasteners for the strainers were cored out and backfilled with epoxy making sure there is not a continuation of this problem. Though hulls that had no strainers fitted metered perfectly dry.

Dave Forsman

LIBERTY, #43