brian eiland

Guru

- Joined

- Jul 17, 2013

- Messages

- 930

- Location

- USA & Thailand

- Vessel Name

- RunningTide

- Vessel Make

- 37 Louisiane catamaran

I have become real intrigued with this vessel design, after only discovering what it was back in Aug 2012.

Help Please, what is this vessel?

http://www.yachtforums.com/forums/general-trawler-discussion/19252-trawler-houseboat.html

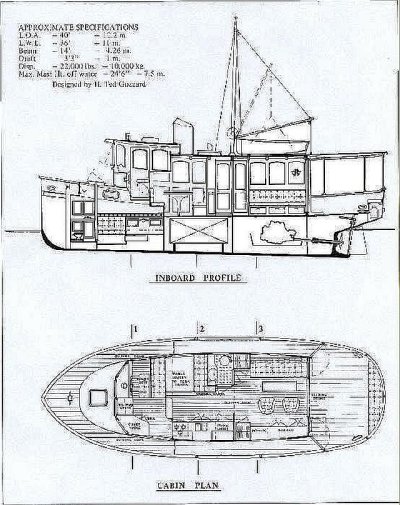

There is a very nostalgic look to this design, and it is VERY live-aboard friendly with its layout. I've lived aboard two different boats on two occasions in my lifetime, and now I'm considering it again, But at my age (70 now) I've come to appreciate certain comforts I would like to have on a vessel. This 40 footer appears to have a nice size galley, a more roomy than most head/shower, a nice saloon/living room, and a very nice covered aft deck.

It reminds me of an older Elco or ACF that I once sought to buy for living aboard back in my college days.,....or even of the Trumpy/Mathis houseboats,...or of a few European canal boats that I've also admired

It has a single 6-cyl diesel engine for power. I've always considered the in-line 6-cyl engine the BEST configuration for a 4-cycle engine. Some of them will run forever as they are inherently the best balanced, and they can give excellent economy.

I just missed buying one of these vessels this past Sept that I thought was in very good condition. Then again I missed a really good buy on one up in Boston several months ago. Turns out there were only about 40 of these vessels built between 1983 & 1989. And even while there have been numbers of inquires as to if any more will ever be built, there appears to be no plans for the production to be resurrected.

http://pilgrim-trawlers.wikidot.com/history

So my thought processes turned to; ….what would it cost to build such a vessel,....what would I change if I were to build such a vessel,...are there like-minded individuals out there that would be interested in owning such a vessel, etc??

This exercise in 'Redesigning the Pilgrim 40' may turn out to just be a mental exercise. It may never happen in reality, but it will be an interesting mental project.

http://pilgrim-trawlers.wikidot.com/

Help Please, what is this vessel?

http://www.yachtforums.com/forums/general-trawler-discussion/19252-trawler-houseboat.html

There is a very nostalgic look to this design, and it is VERY live-aboard friendly with its layout. I've lived aboard two different boats on two occasions in my lifetime, and now I'm considering it again, But at my age (70 now) I've come to appreciate certain comforts I would like to have on a vessel. This 40 footer appears to have a nice size galley, a more roomy than most head/shower, a nice saloon/living room, and a very nice covered aft deck.

It reminds me of an older Elco or ACF that I once sought to buy for living aboard back in my college days.,....or even of the Trumpy/Mathis houseboats,...or of a few European canal boats that I've also admired

It has a single 6-cyl diesel engine for power. I've always considered the in-line 6-cyl engine the BEST configuration for a 4-cycle engine. Some of them will run forever as they are inherently the best balanced, and they can give excellent economy.

I just missed buying one of these vessels this past Sept that I thought was in very good condition. Then again I missed a really good buy on one up in Boston several months ago. Turns out there were only about 40 of these vessels built between 1983 & 1989. And even while there have been numbers of inquires as to if any more will ever be built, there appears to be no plans for the production to be resurrected.

http://pilgrim-trawlers.wikidot.com/history

So my thought processes turned to; ….what would it cost to build such a vessel,....what would I change if I were to build such a vessel,...are there like-minded individuals out there that would be interested in owning such a vessel, etc??

This exercise in 'Redesigning the Pilgrim 40' may turn out to just be a mental exercise. It may never happen in reality, but it will be an interesting mental project.

http://pilgrim-trawlers.wikidot.com/

!!!

!!!