. Now that's a Great Loop boat if I've ever seen one!In our marina today . Home built based on Dutch canal boat built from 300 plus sheets Doug fir ply 3 layers thick Powered by 2 ea 75 hp beta marine Kabota's . Sorry not the best picture.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Redesigning the Pilgrim 40 Trawler / Canal Boat

- Thread starter brian eiland

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Pack Mule

TF Site Team

- Joined

- Jan 24, 2013

- Messages

- 3,749

- Location

- USA

- Vessel Name

- Slo-Poke

- Vessel Make

- Jorgensen custom 44

It was a cool looking boat that's for sure .I misunderstood the owner,my wife said he said he ued 200 plus sheets of plywood .I've been trying to figure out the 300 and can't come up with that many. He said it took him 17 years to build. It's only been in the water a few months. It was built in Ohio . He glassed over the structure with I think he said with 2 layers of 120z mat. It was 58' long and the beam must have been around 15 ft.The bow and stern were rounded off. It had a full size entry door on the stern just above the swim ladder. It was wild looking . The pilot house really gave it a salty look.. Now that's a Great Loop boat if I've ever seen one!

brian eiland

Guru

- Joined

- Jul 17, 2013

- Messages

- 930

- Location

- USA & Thailand

- Vessel Name

- RunningTide

- Vessel Make

- 37 Louisiane catamaran

Pilgrim 50 footer ?

I was just getting ready to post a few more 'construction related' postings when I ran across this,....sure looks like a Pilgrim 40 design, but a 50 footer.

http://www.yachtworld.com/boats/1987/Custom-Trawler--2295184/Sanford/FL/United-States#.UnuYE38o7IV

Says it was built in 1987, so that's about midway thru the production schedule of the original 40's,...1984-1989. I imagine this person was quite intrigued with the original design, but wanted something a little bigger. Haven't been able to sort out the actual designer, nor builder yet

I've talked with this lady broker

Linda Reynolds, lindar@masseyyacht.com

She made these videos:

Video of Resolute Exterior

Video of Resolute Interior

I was just getting ready to post a few more 'construction related' postings when I ran across this,....sure looks like a Pilgrim 40 design, but a 50 footer.

http://www.yachtworld.com/boats/1987/Custom-Trawler--2295184/Sanford/FL/United-States#.UnuYE38o7IV

Says it was built in 1987, so that's about midway thru the production schedule of the original 40's,...1984-1989. I imagine this person was quite intrigued with the original design, but wanted something a little bigger. Haven't been able to sort out the actual designer, nor builder yet

I've talked with this lady broker

Linda Reynolds, lindar@masseyyacht.com

She made these videos:

Video of Resolute Exterior

Video of Resolute Interior

Last edited:

URL="http://www.yachtworld.com/boats/1987/Custom-Trawler--2295184/Sanford/FL/United-States#.UnuYE38o7IV"]http://www.yachtworld.com/boats/1987/Custom-Trawler--2295184/Sanford/FL/United-States#.UnuYE38o7IV[/URL]

Looks like a great liveaboard or great loop boat.

drf6

Veteran Member

I imagine this person was quite intrigued with the original design, but wanted something a little bigger. Haven't been able to sort out the actual designer, nor builder yet

The designer is listed as Don Wilson (under the Full Specifications Tab on the Yachtworld posting).

brian eiland

Guru

- Joined

- Jul 17, 2013

- Messages

- 930

- Location

- USA & Thailand

- Vessel Name

- RunningTide

- Vessel Make

- 37 Louisiane catamaran

I saw that, but when I tried to find a boat designer named Don Wilson I got another Ed Wilson down in Tampa, St Pete area, and that turned out to be incorrect. Would have to do more research to find that fellow, or perhaps he is deceased?

I asked the broker if she might know of where a 'layout plan' might be for the vessel, and/or designer/builder info, but have not got an answer to those questions yet.

Strange that the fwd stateroom was not in the photos of the vessel, but does appear on the video of the interior.

I asked the broker if she might know of where a 'layout plan' might be for the vessel, and/or designer/builder info, but have not got an answer to those questions yet.

Strange that the fwd stateroom was not in the photos of the vessel, but does appear on the video of the interior.

Last edited:

Strange that the fwd stateroom was not in the photos of the vessel, but does appear on the video of the interior.

My guess is the "functional" stateroom as it is described on the videos isn't the greatest of selling points. It appears the two double berths are cranium to cranium in one open room in the bow, no?

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

I saw this boat some time ago, but I couldn't get over the overwhelming upper deck. I've got no problems with fly-bridges but on a boat like this, I think the style is so classic that unless you're charting dinner groups or tours of canals, why compromise the style of the boat. Here, I've cropped the upper deck in favor of a reasonable fly-bridge, and took the ladder off its dead center position in front of the helm. It's probably what I'd do if the boat was mine.

Attachments

brian eiland

Guru

- Joined

- Jul 17, 2013

- Messages

- 930

- Location

- USA & Thailand

- Vessel Name

- RunningTide

- Vessel Make

- 37 Louisiane catamaran

I'd have to agree with you on that 'overwhelming upper deck' on the classic look of the vessel. I even think that lifeline covering around the aft upper deck is a distraction.

I'm still not even happy with the flybridge awning you've retained Healhustler. It just appears too tall, out of proportion. I mentioned this 'flybridge' subject back on this posting #121.

Trawler Forum - View Single Post - Redesigning the Pilgrim 40 Trawler / Canal Boat

I wonder why all of the sun awnings on these flybridge-equipped Pilgrims appear to be the same design, and also a little too tall for my liking. I would like to look at the possibility that the awning, when retracted, would fold forward across the front edge of the flybridge console

And why must they be so tall? I understand you might wish to stand-up sometimes under this awning, but the great majority of time you are seated under it. Besides if it were lower in height, would it not do a better job at providing shade at lower sun angles. In that case it might require a smaller canopy area to provide the same protection from the sun?

I can understand your desire to remove that unsightly front ladder to the top deck. I imagine that al older fellow ad this boat designed, and it was his desire to have easier access to the top deck rather than transitioning always to the aft deck to climb up to the upper deck, and/or a flybridge control station. Wonder what other alternatives to the single aft deck access are on a private vessel? And perhaps a 'dumb waiter' arrangement is needed to provide snacks and drinks to the skipper at the flybridge controls, in lieu of bringing them up via the aft ladder/stairs?

I'm still not even happy with the flybridge awning you've retained Healhustler. It just appears too tall, out of proportion. I mentioned this 'flybridge' subject back on this posting #121.

Trawler Forum - View Single Post - Redesigning the Pilgrim 40 Trawler / Canal Boat

I wonder why all of the sun awnings on these flybridge-equipped Pilgrims appear to be the same design, and also a little too tall for my liking. I would like to look at the possibility that the awning, when retracted, would fold forward across the front edge of the flybridge console

And why must they be so tall? I understand you might wish to stand-up sometimes under this awning, but the great majority of time you are seated under it. Besides if it were lower in height, would it not do a better job at providing shade at lower sun angles. In that case it might require a smaller canopy area to provide the same protection from the sun?

I can understand your desire to remove that unsightly front ladder to the top deck. I imagine that al older fellow ad this boat designed, and it was his desire to have easier access to the top deck rather than transitioning always to the aft deck to climb up to the upper deck, and/or a flybridge control station. Wonder what other alternatives to the single aft deck access are on a private vessel? And perhaps a 'dumb waiter' arrangement is needed to provide snacks and drinks to the skipper at the flybridge controls, in lieu of bringing them up via the aft ladder/stairs?

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

I'm still not even happy with the flybridge awning you've retained Healhustler. It just appears too tall, out of proportion.

I agree, it looks rediculous on this kind of style. But if you're going to have a functional fly-bridge where you can stand to see the corners of the boat while docking, down here in FL you gotta have something to make it practical. For sure, I'd do without it if I could, but I think the boat can handle a fly-bridge the basic FB structure like this OK. A proper mast and boom might help with the balance.

Attachments

brian eiland

Guru

- Joined

- Jul 17, 2013

- Messages

- 930

- Location

- USA & Thailand

- Vessel Name

- RunningTide

- Vessel Make

- 37 Louisiane catamaran

Man-Hrs for Steel Hull Construction (part 1)

I think its time to take a more direct approach to this question of the cost to build this redesigned trawler I am proposing. We need to go to some steel boat fabricators and see if we can get some quotes from them to build the hull shell portion of the vessel. I suspect we will have several problems with our obtaining these estimates as:

1) I do not have the definitive hull design yet, nor the specific details that will be associated with that design,

2) I don't yet have a positive indication that the project will go forward, but favorable (yet honest) pricing estimates might help.

But lets go forward and see if we can figure out the 'man-hrs' needed to build the steel hull portion of this project. To make matters less confusing lets try to keep 'dollar figures' out of this estimate, and deal with the man-hrs needed. Then the project can be priced out at different labor rates that can exist in different regions of the USA, and/or other foreign building locations.

With Tad's considerable experience, I would ask that he also give us an estimate / guesstimate to finish this portion of the build.

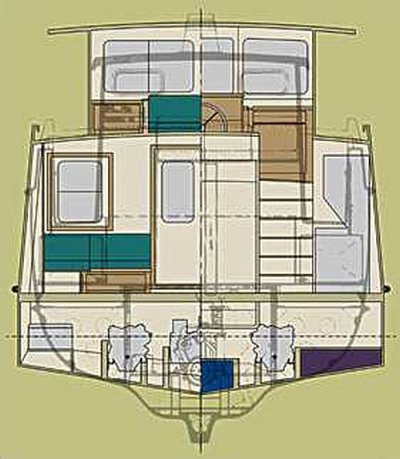

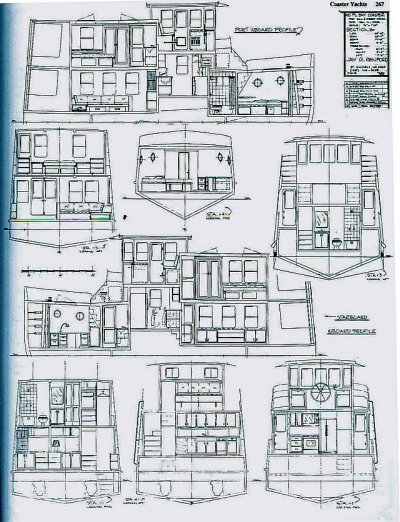

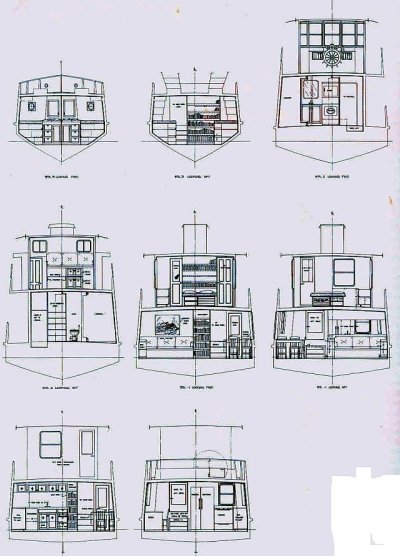

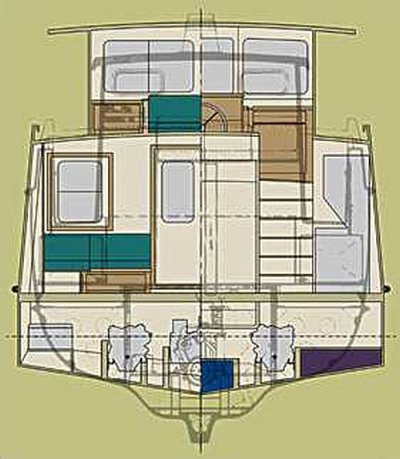

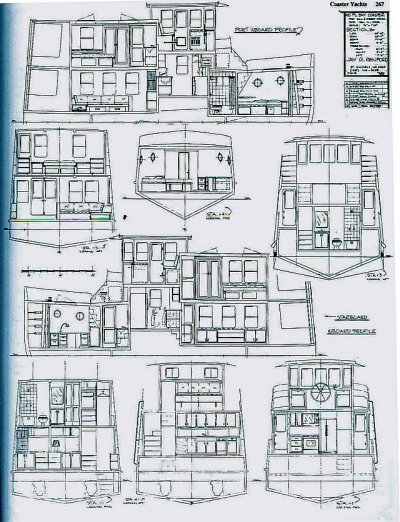

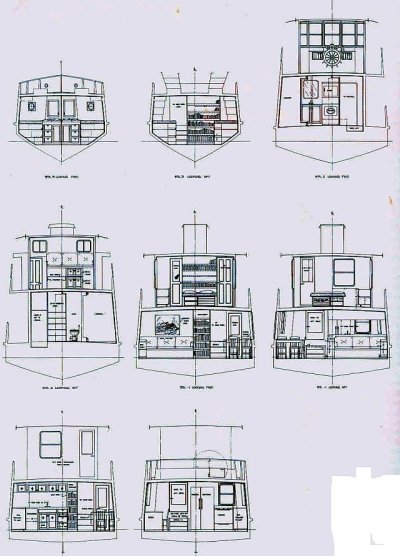

Lets choose the hull design to be considered for this estimating exercise. The more I study the options, the more convinced I've become that the hull forms offered by the Florida Bay Coasters and the great Harbor Trawlers are a very favorable choice for this displacement speed Pilgrim. The hulls from both of these designs are very similar designs and have a documented favorable track record. Their hard chines, and considerable flat panel areas lend themselves to relatively easy fabrication in metal.

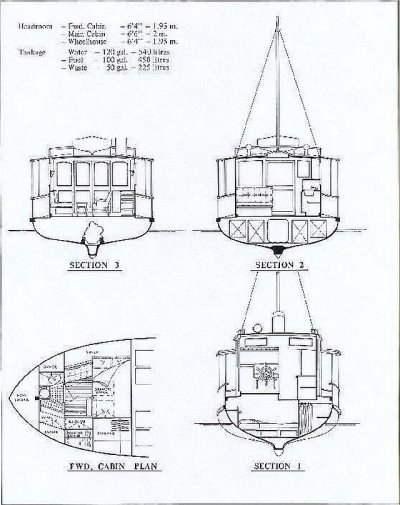

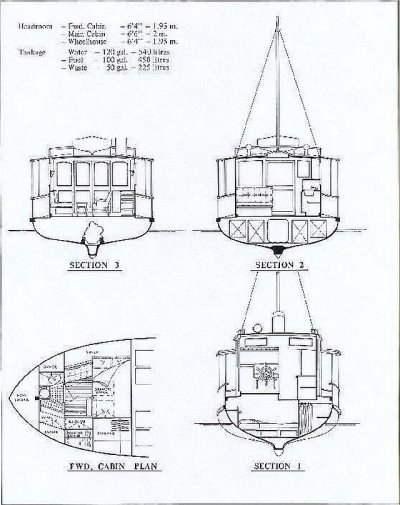

Look at a few of these hull cross-sections and photos.

First a few of the original Pilgrim design.

Then an overlaid depiction of that Pilgrim hull type, compared to the hard chine section of a Great Harbor hull.

Here are a few hull sections of the Fla Bay Coaster hard chine type

…..and some photos of these Fla Bay coaster hull types,

This is NOT a really difficult hull shape to build.....lots of 'flat' or single curvature panels, and no mult-chine.

I think its time to take a more direct approach to this question of the cost to build this redesigned trawler I am proposing. We need to go to some steel boat fabricators and see if we can get some quotes from them to build the hull shell portion of the vessel. I suspect we will have several problems with our obtaining these estimates as:

1) I do not have the definitive hull design yet, nor the specific details that will be associated with that design,

2) I don't yet have a positive indication that the project will go forward, but favorable (yet honest) pricing estimates might help.

But lets go forward and see if we can figure out the 'man-hrs' needed to build the steel hull portion of this project. To make matters less confusing lets try to keep 'dollar figures' out of this estimate, and deal with the man-hrs needed. Then the project can be priced out at different labor rates that can exist in different regions of the USA, and/or other foreign building locations.

With Tad's considerable experience, I would ask that he also give us an estimate / guesstimate to finish this portion of the build.

Lets choose the hull design to be considered for this estimating exercise. The more I study the options, the more convinced I've become that the hull forms offered by the Florida Bay Coasters and the great Harbor Trawlers are a very favorable choice for this displacement speed Pilgrim. The hulls from both of these designs are very similar designs and have a documented favorable track record. Their hard chines, and considerable flat panel areas lend themselves to relatively easy fabrication in metal.

Look at a few of these hull cross-sections and photos.

First a few of the original Pilgrim design.

Then an overlaid depiction of that Pilgrim hull type, compared to the hard chine section of a Great Harbor hull.

Here are a few hull sections of the Fla Bay Coaster hard chine type

…..and some photos of these Fla Bay coaster hull types,

This is NOT a really difficult hull shape to build.....lots of 'flat' or single curvature panels, and no mult-chine.

I would likely go one step further and do a more complete review of a variation on the FBC hull design that Jay Benford did, his design #295, a “West Coaster” for a gentleman who lived in California. That client wanted similar livability, plus more ability to deal with open ocean cruising. To achieve this Jay modified the hull form, particularly in the bow, giving it a finer entry and more flare.

Last edited:

brian eiland

Guru

- Joined

- Jul 17, 2013

- Messages

- 930

- Location

- USA & Thailand

- Vessel Name

- RunningTide

- Vessel Make

- 37 Louisiane catamaran

brian eiland

Guru

- Joined

- Jul 17, 2013

- Messages

- 930

- Location

- USA & Thailand

- Vessel Name

- RunningTide

- Vessel Make

- 37 Louisiane catamaran

Man-Hrs for Steel Hull Construction (part 2)

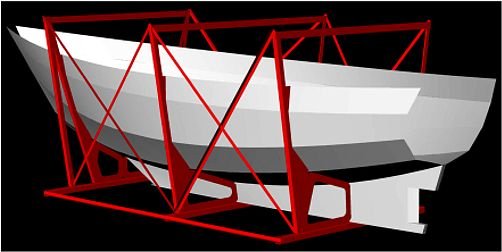

Now picture building the single-chine hull shells in a the 'frameless' construction method, Ie,....'plate first, frames second' pictured here:

This should be even easier with the 'coaster style hulls', ...certainly even easier than the multi-chined sailboat hulls being built in these photos.

Mike Kasten presents a pretty clear explanation of the pros and cons of the frameless metal hull construction here:

Frames First or Plating First...?

HULL PLATING

For purposes of this estimate lets specify 6-mm hull plating of pre-primed steel for both the bottom and the topsides. The steel topsides will be extended up to just above the deck level, and there it will transition into honeycomb composite panels for the 'topsides railing' around the vessel. The upper edges of the steel hull-shell will provide a steel ledge all-around to support the composite main deck. The steel hull-shell will also provide supports for the tubular verticals that support the outer edges of the upper deck (saloon roof). Those details are yet to be specified, but hopefully will be relatively simple in design.

STRINGERS (& Fuel Tanks)

There should be 2 major stringers running about 2/3 the length of the vessel, from under the fwd stateroom aft to the bulkhead below the end of the saloon (just before the lazarette). These stringers will provide support for the single main engine and the generator unit.

There should be 2 each minor stringers to each side of the principle engine stringers. These minor ones may not be 'continuous' by their nature, as I anticipate two sizable internal fuel tanks to be built-in at the beam sides about midway of the hull's length.The inner vertical walls of these fuel tanks will act as stringers, and furthermore some internal baffle plates will act as hull-plate stiffeners also.

BULKHEADS

There should be 5 full bulkheads positioned down the length of the vessel. They should look something like this....

...with cut-out lightening holes and top flanges to support the composite deck panel. These bulkheads backup the stringer system, support the main-deck/ floor, and help maintain the firm width of the hull-shell at deck level.

KEEL, RUDDER

Unlike the the Fla Bay Coasters & the Great Harbor Trawlers, this vessel will be a single-engine vessel with a single keel and a single rudder fashioned in a standard manor.

CNC CUT STEEL

All of the steel work will be pre-cut from computer files, and be of the pre-primed nature. The steel hull fabricator does NOT have to include the cost of this steel material in his estimate to 'construct' the hull-shell. BUT it would be VERY helpful if he could supply some estimates of this material costs based upon his past experiences?

CORRSION PROTECTION

As noted above the steel will come to the builder in a pre-primed condition rather than raw mill steel.

The hull fabricator will NOT have to be concerned with any type of finishing (painting, priming, etc) of the 'exterior' surfaces of the hull-shell,....other than touch-up priming of those spots he 'disturbs' when he tack-welds the hull plating to the jig support fixture.

However the fabricator will be responsible for the interior surfaces of the hull-shell. We seek to provide a really durable, easily maintained surface to bilge areas, the internal steel hull plating and framing. Its been recommended that all 'mating' pieces of steel (ie, stringers to hull plating, stringers to bulkheads, etc), be sealed with a polyurethane chalking such as Sikaflex or equivalent, to prevent moisture and air from getting at the undercuts, etc that might not be so easily coated with the final primer and epoxies that will be applied to these bilge areas.

The hull fabricator will be responsible for this full coating of primer and epoxy coating of the interior surfaces of the hull-shell, and shall also coat the interior surfaces of the built in fuel tanks and baffles prior to placing a top on them.

Last edited:

- Joined

- Jun 25, 2008

- Messages

- 10,104

- Location

- Australia

- Vessel Name

- Now boatless - sold 6/2018

- Vessel Make

- Had a Clipper (CHB) 34

Brian Eiland wrote…...CORRSION PROTECTION

As noted above the steel will come to the builder in a pre-primed condition rather than raw mill steel.

The hull fabricator will NOT have to be concerned with any type of finishing (painting, priming, etc) of the 'exterior' surfaces of the hull-shell,....other than touch-up priming of those spots he 'disturbs' when he tack-welds the hull plating to the jig support fixture.

However the fabricator will be responsible for the interior surfaces of the hull-shell. We seek to provide a really durable, easily maintained surface to bilge areas, the internal steel hull plating and framing. Its been recommended that all 'mating' pieces of steel (ie, stringers to hull plating, stringers to bulkheads, etc), be sealed with a polyurethane chalking such as Sikaflex or equivalent, to prevent moisture and air from getting at the undercuts, etc that might not be so easily coated with the final primer and epoxies that will be applied to these bilge areas.

The hull fabricator will be responsible for this full coating of primer and epoxy coating of the interior surfaces of the hull-shell, and shall also coat the interior surfaces of the built in fuel tanks and baffles prior to placing a top on them.

Brian, have you considered building in alloy, in light of all the extra steps to ensure good corrosion protection using steel, especially in a marine environment..? There was an alloy (45' I think) Florida Bay Coaster built over here in Australia, which worked out very well in terms of cost comparison and seaway performance, especially once a bit more ballast was added low down. I went over her at a Sanctuary Cove Boat Show some years ago now, and she was beautifully finished. It was hard to believe it was not fibreglass.

I see she's for sale - maybe you don't need to build one from scratch - why re-invent a good wheel, as they say..?

Boats For Sale - powered by YachtHub - Bosuns Locker

As noted above the steel will come to the builder in a pre-primed condition rather than raw mill steel.

The hull fabricator will NOT have to be concerned with any type of finishing (painting, priming, etc) of the 'exterior' surfaces of the hull-shell,....other than touch-up priming of those spots he 'disturbs' when he tack-welds the hull plating to the jig support fixture.

However the fabricator will be responsible for the interior surfaces of the hull-shell. We seek to provide a really durable, easily maintained surface to bilge areas, the internal steel hull plating and framing. Its been recommended that all 'mating' pieces of steel (ie, stringers to hull plating, stringers to bulkheads, etc), be sealed with a polyurethane chalking such as Sikaflex or equivalent, to prevent moisture and air from getting at the undercuts, etc that might not be so easily coated with the final primer and epoxies that will be applied to these bilge areas.

The hull fabricator will be responsible for this full coating of primer and epoxy coating of the interior surfaces of the hull-shell, and shall also coat the interior surfaces of the built in fuel tanks and baffles prior to placing a top on them.

Brian, have you considered building in alloy, in light of all the extra steps to ensure good corrosion protection using steel, especially in a marine environment..? There was an alloy (45' I think) Florida Bay Coaster built over here in Australia, which worked out very well in terms of cost comparison and seaway performance, especially once a bit more ballast was added low down. I went over her at a Sanctuary Cove Boat Show some years ago now, and she was beautifully finished. It was hard to believe it was not fibreglass.

I see she's for sale - maybe you don't need to build one from scratch - why re-invent a good wheel, as they say..?

Boats For Sale - powered by YachtHub - Bosuns Locker

brian eiland

Guru

- Joined

- Jul 17, 2013

- Messages

- 930

- Location

- USA & Thailand

- Vessel Name

- RunningTide

- Vessel Make

- 37 Louisiane catamaran

Yes Peter, aluminum is still under consideration, but not at the top of the list at the moment. It certainly can be done.

That vessel you referenced is I believe a 38 footer that appears in the last photo example I posted above. There is also an allot 55 foot Benford design that is being completed over in NZ right now.

But neither of these vessels are a Pilgrim design. And both of them are quite a bit more expensive (over $500K) than I'm shooting for with this redesign effort.

That vessel you referenced is I believe a 38 footer that appears in the last photo example I posted above. There is also an allot 55 foot Benford design that is being completed over in NZ right now.

But neither of these vessels are a Pilgrim design. And both of them are quite a bit more expensive (over $500K) than I'm shooting for with this redesign effort.

hollywood8118

Guru

- Joined

- Nov 16, 2009

- Messages

- 2,379

- Location

- USA

- Vessel Name

- " OTTER "

- Vessel Make

- Ocean Alexander Europa 40

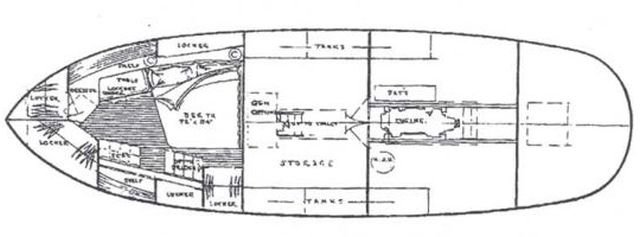

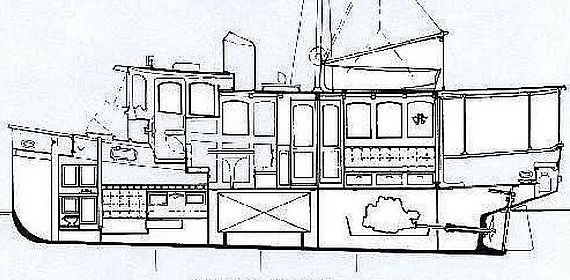

Slight Digression

Here is another hull shape I'd like to consider for this Pilgrim redesign. It's like a mini commercial fishing type. It was utilized on the custom built IslandEagle vessel owned by one of this forum's members.

View attachment 24489

View attachment 24490

View attachment 24491

Now that is a great looking vessel!

HOLLYWOOD

Tad Roberts

Guru

Brian,

Watch a few of these....er....watch a lot of the SV Seeker videos to see where the time goes in boatbuilding. See their difficulties in getting the skeg (engine cooling) pressure tight. This is why most boat builders prefer tanks built outside the boat where they have lots of working space and welds are easy to inspect and test. Integral tanks add lots of hours and expense.

http://www.submarineboat.com/sailboat.htm

Watch a few of these....er....watch a lot of the SV Seeker videos to see where the time goes in boatbuilding. See their difficulties in getting the skeg (engine cooling) pressure tight. This is why most boat builders prefer tanks built outside the boat where they have lots of working space and welds are easy to inspect and test. Integral tanks add lots of hours and expense.

http://www.submarineboat.com/sailboat.htm

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

There was an alloy (45' I think) Florida Bay Coaster built over here in Australia, which worked out very well in terms of cost comparison and seaway performance, especially once a bit more ballast was added low down. I went over her at a Sanctuary Cove Boat Show some years ago now, and she was beautifully finished. It was hard to believe it was not fibreglass.

I see she's for sale - maybe you don't need to build one from scratch - why re-invent a good wheel, as they say..?

Boats For Sale - powered by YachtHub - Bosuns Locker

Yeah, I remember when that boat was under construction. Looks as if they did a very nice job. Thank heavens that one is in OZ, cuz my Admiral won't see it. Thanks for posting this one, Peter. I was struck by the proper ground tackle..... two 100 plus kilogram Mansons plus chain and "wire" instead of rode and a winch to handle it. That should hold it.

- Joined

- Jun 25, 2008

- Messages

- 10,104

- Location

- Australia

- Vessel Name

- Now boatless - sold 6/2018

- Vessel Make

- Had a Clipper (CHB) 34

Yeah, I remember when that boat was under construction. Looks as if they did a very nice job. Thank heavens that one is in OZ, cuz my Admiral won't see it. Thanks for posting this one, Peter. I was struck by the proper ground tackle..... two 100 plus kilogram Mansons plus chain and "wire" instead of rode and a winch to handle it. That should hold it.

Sorry Heal, but as I see it, that;'s a Bruce/Claw type anchor thingy poking out the from hawse pipe, and to me, the only non-Brownie point on the fit-out. But hey…a cinch to swap it for a Super Sarca or Excel, even a Rocna or Manson Supreme at a pinch...

Last edited:

Bilgewater

Senior Member

- Joined

- Jun 20, 2011

- Messages

- 276

- Location

- USA

- Vessel Name

- Sunset Lady

- Vessel Make

- 1975 Chris Craft 35 Aft Cabin

Looking at the boat will all the top side awnings and such, I expected to see Steve McQueen to come up from below decks of the "Sand Pebbles".

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

Sorry Heal, but as I see it, that;'s a Bruce/Claw type anchor thingy poking out the from hawse pipe, and to me, the only non-Brownie point on the fit-out. But hey…a cinch to swap it for a Super Sarca or Excel, even a Rocna or Manson Supreme at a pinch...

That's true....it does look like a claw. I was just reading the spec's as published:

Ground Tackle:

2 x Manson 115kg Anchors. Chain. Hydraulic Winch with 30 meters of chain and 100 meters of wire.

Did Manson make a claw too? Never knew that.

brian eiland

Guru

- Joined

- Jul 17, 2013

- Messages

- 930

- Location

- USA & Thailand

- Vessel Name

- RunningTide

- Vessel Make

- 37 Louisiane catamaran

Brian,

Watch a few of these....er....watch a lot of the SV Seeker videos to see where the time goes in boatbuilding. See their difficulties in getting the skeg (engine cooling) pressure tight. This is why most boat builders prefer tanks built outside the boat where they have lots of working space and welds are easy to inspect and test. Integral tanks add lots of hours and expense.

http://www.submarineboat.com/sailboat.htm

Tad, thanks for posting that link. From the looks of the 'table of contents' on that site I would guess there are some things to learn. I've only had time to look that far, so far, but I will surely review it

brian eiland

Guru

- Joined

- Jul 17, 2013

- Messages

- 930

- Location

- USA & Thailand

- Vessel Name

- RunningTide

- Vessel Make

- 37 Louisiane catamaran

I've done a 'reading' (non-video) review of quite a number of those subheadings under that website you referenced, and to tell the truth I was not that impressed. It seems to me that that site might be very helpful to a 'do-it-yourself' welder who was considering a metal boat,...lots of 'beginning welder' info.Tad, thanks for posting that link. From the looks of the 'table of contents' on that site I would guess there are some things to learn. I've only had time to look that far, so far, but I will surely review it

I don't plan on taking up welding to do this project, but rather subcontract that out to an experienced metal shop. So I would think they would already have lots of experience that this beginning welder is discovering. I got more good advice over here:

STEEL HULLS with Composite Superstructure / Topsides - Boat Design Forums

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

Two items I would want on any along shore cruiser is a set of chain plates (4) so the boat could be hoisted on a ship with no extra gear .

And a bottom strong enough that no cradle would be required , only some blocks or cribbing so the boat could be secured.

Crossing real water aboard a ship opens the world to a basically inshore vessel.

And at low cost too! Cruise the Amazon? Cruise Chinas rivers? Why not?

And a bottom strong enough that no cradle would be required , only some blocks or cribbing so the boat could be secured.

Crossing real water aboard a ship opens the world to a basically inshore vessel.

And at low cost too! Cruise the Amazon? Cruise Chinas rivers? Why not?

Two items I would want on any along shore cruiser is a set of chain plates (4) so the boat could be hoisted on a ship with no extra gear .

And a bottom strong enough that no cradle would be required , only some blocks or cribbing so the boat could be secured.

Crossing real water aboard a ship opens the world to a basically inshore vessel.

And at low cost too! Cruise the Amazon? Cruise Chinas rivers? Why not?

Based on this idea many boats in Holland and Germany are equipped with so-called "Wadden Sea Legs"

Nomad Willy

Guru

Hustler,

Yes Manson does make a Claw. It's a high end unit fabricated and welded not cast. Also the most expensive Clanw I've ever seen. It's called the "Ray".

Manson make several types of anchors not locked into one type and selling it as the "only anchor for you".

Yes Manson does make a Claw. It's a high end unit fabricated and welded not cast. Also the most expensive Clanw I've ever seen. It's called the "Ray".

Manson make several types of anchors not locked into one type and selling it as the "only anchor for you".

Last edited:

SaltyDog

Senior Member

- Joined

- Nov 11, 2007

- Messages

- 251

Two items I would want on any along shore cruiser is a set of chain plates (4) so the boat could be hoisted on a ship with no extra gear .

And a bottom strong enough that no cradle would be required , only some blocks or cribbing so the boat could be secured.

Crossing real water aboard a ship opens the world to a basically inshore vessel.

And at low cost too! Cruise the Amazon? Cruise Chinas rivers? Why not?

Sounds like a better idea than one that fits in a shipping container. While the idea of the shipping container IS one I like, it does limit the design.

If made of steel the cost would make it one of the highest returns on investment feature discussed so far.

Keep it cheap, simple and then wear it out!

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

Sounds like a better idea than one that fits in a shipping container. While the idea of the shipping container IS one I like, it does limit the design.

The advantage of the container , cheap shipping with out the boat being stripped as a RO RO or deck cargo would be is easy to uderstand.

The very skinny hull that is easily beachable would be as wide as many sail boats and would have a similar layout .

The big advantage would be cheap speed. 3GPH at 18K with about 1GPH or a bit more at 12K would open cruising grounds at low coat .

But the beam overall is only 7.5 ft so it is not for the beach ball shaped roomeran crowd. A Fwd cockpit (like Midnight Lace) in stead of an oxygen tent , and other accomidations would need to be made.

The advantage of the container , cheap shipping with out the boat being stripped as a RO RO or deck cargo would be is easy to uderstand.

The very skinny hull that is easily beachable would be as wide as many sail boats and would have a similar layout .

The big advantage would be cheap speed. 3GPH at 18K with about 1GPH or a bit more at 12K would open cruising grounds at low coat .

But the beam overall is only 7.5 ft so it is not for the beach ball shaped roomeran crowd. A Fwd cockpit (like Midnight Lace) in stead of an oxygen tent , and other accomidations would need to be made.

AusCan

Guru

- Joined

- Jul 15, 2012

- Messages

- 3,218

- Location

- Australia

- Vessel Name

- Kokanee

- Vessel Make

- Cuddles 30 Pilot House Motor Sailer

Here's a boat with a few similarities that uses steadying sails to control roll. I don't know how effective they are on this application, but its claimed the boat has circumnavigated Australia, which involves handling some big swell.

Used John Pugh Vacationer 42 for Sale | Boats For Sale | Yachthub

Used John Pugh Vacationer 42 for Sale | Boats For Sale | Yachthub

brian eiland

Guru

- Joined

- Jul 17, 2013

- Messages

- 930

- Location

- USA & Thailand

- Vessel Name

- RunningTide

- Vessel Make

- 37 Louisiane catamaran

American Tug 34

Have a look at a few of the postings and photos over here of this American Tug model....impressive for its size. !!

http://www.trawlerforum.com/forums/s3/what-does-your-boat-look-like-1274-7.html

It does appear as though it has 'grown'

Have a look at a few of the postings and photos over here of this American Tug model....impressive for its size. !!

http://www.trawlerforum.com/forums/s3/what-does-your-boat-look-like-1274-7.html

It does appear as though it has 'grown'

But they were able to start out with a very good introductory price.While the boat was originally designated an AT 34, it is now referred to as an AT 365 as it measures 36 ft 6 in.

They had that hull #1 at the Miami Boat Show for $199k!!!! I remember thinking what a great deal that was at the time. I know they are much more expensive now and can't find a used one at that price.

Last edited:

Similar threads

- Replies

- 25

- Views

- 2K

- Replies

- 12

- Views

- 1K