brian eiland

Guru

- Joined

- Jul 17, 2013

- Messages

- 930

- Location

- USA & Thailand

- Vessel Name

- RunningTide

- Vessel Make

- 37 Louisiane catamaran

Flying Bridge ??

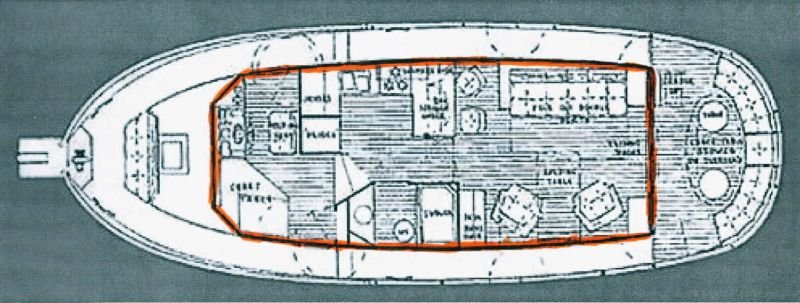

I've been looking thru Jay Benford's book 'Small Ships' just recently and I ran into this illustration of one variation of his 35' Pacquette design:

http://www.benford.us/pdf/35Trawler.pdf

It got me to thinking about 'combining' the upper and lower helm stations of the flybridge model Pilgrim into a single pilot station raised higher than the original one, and provided with lots of ventilation as one might experience in the flying bridge, but without requiring the additional sun awning. One station, without duplication of steering gear and instrumentation.

Plus it would allow for more headroom in that fwd berth area. I think it could be incorporated into the design without any great disruption of the original design, and actually be more appealing than the flybridge add-on with its ever taller awning??

To my eye, (and that's of course entirely subjective) I think the flybridge cowling detracts from the general lines of the boat. Somebody posted an early sketch of this design without the flybridge. Much better. Especially from the front quarter views, the boat seems (to me, at least) to look unnecessarily top heavy.

The flybridge looks out of place, sort of like somebody stuck a stovepipe hat on a Hollywood starlet. Opinions will differ of course, but that's mine.

But life is simpler/basic without a flying bridge!

I've been looking thru Jay Benford's book 'Small Ships' just recently and I ran into this illustration of one variation of his 35' Pacquette design:

http://www.benford.us/pdf/35Trawler.pdf

It got me to thinking about 'combining' the upper and lower helm stations of the flybridge model Pilgrim into a single pilot station raised higher than the original one, and provided with lots of ventilation as one might experience in the flying bridge, but without requiring the additional sun awning. One station, without duplication of steering gear and instrumentation.

Plus it would allow for more headroom in that fwd berth area. I think it could be incorporated into the design without any great disruption of the original design, and actually be more appealing than the flybridge add-on with its ever taller awning??

Attachments

Last edited: