The recent thread "Off to the Abacos," relates a control failure while backing the forum member's boat, a Nordhavn, into a slip. Reportedly, his shifter was in neutral when it spontaneously shifted into reverse, and increased the engine RPMs. The skipper heard the revs increase, and acted fast to stop the engine. No injuries, so it could have been much worse. But, this story has seriously ratcheted-up my skepticism about MMCs. Many builders install them, and I would expect top-shelf original equipment from PAE, builders of Nordhavn.

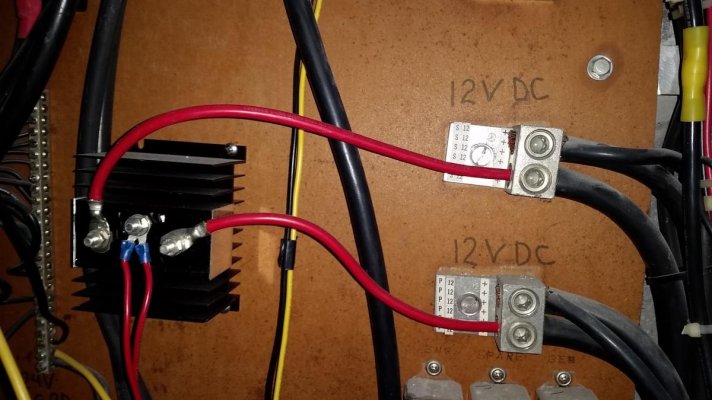

Shipbuilders like electronic shifters and throttles because they are cheap to install - no cables, no pulleys and sheaves, no plumbing (as with hydraulic or pneumatic controls). Just run some wires, then "plug and play." MMCs came installed by the builder on a commercial boat I used to run. From the beginning, I didn't care for them, and I liked 'em even less when a 12-volt glitch left me without engine control moments after dropping the dock lines. Again, no harm done, but it could have been worse.

On another TF thread last week I was defending electronic engine controls, a position I'm not so strong on at the moment. Strictly speaking, I guess EEC does not include fly-by-wire throttles, since the latter are ordinarily not part of the engine manufacturer's configuration. But I note that ZF, the big marine gear manufacturer, now seems to own Mather (the first "M" in MMC). The technology has become ubiquitous.

I wonder how many users have had trouble with MMCs or other brands of electronic throttles and shifters?

Shipbuilders like electronic shifters and throttles because they are cheap to install - no cables, no pulleys and sheaves, no plumbing (as with hydraulic or pneumatic controls). Just run some wires, then "plug and play." MMCs came installed by the builder on a commercial boat I used to run. From the beginning, I didn't care for them, and I liked 'em even less when a 12-volt glitch left me without engine control moments after dropping the dock lines. Again, no harm done, but it could have been worse.

On another TF thread last week I was defending electronic engine controls, a position I'm not so strong on at the moment. Strictly speaking, I guess EEC does not include fly-by-wire throttles, since the latter are ordinarily not part of the engine manufacturer's configuration. But I note that ZF, the big marine gear manufacturer, now seems to own Mather (the first "M" in MMC). The technology has become ubiquitous.

I wonder how many users have had trouble with MMCs or other brands of electronic throttles and shifters?