Anyone have any stats on what failures are common for these injection pumps?

I do not have numbers, only the experiences relayed to me by acquaintances in the UK who spent a good chunk of their careers dealing with the Ford of England diesels, including the Dorset.

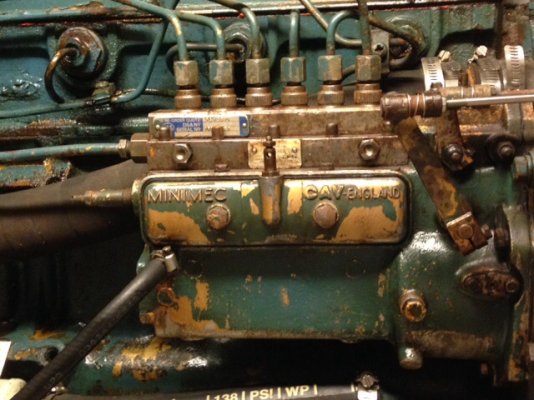

One of the reasons the Dorset proved to be a monumental failure in over-the-road truck service, which is what it was originally designed for in the late 1950s, were weaknesses in the engine that were exacerbated by the very nature of truck operations--- widely and rapidly varying loads on the engine, constant rpm changes, and so forth. The engine's two greatest weaknesses according to these acquaintances are the head gasket, which is prone to blowing under high heat, high load conditions, and the in-line, jerk-injection pump.

Anecdotal problems with the pump included comments like "it needed adjusting all the time" to "it broke a lot" and so on. But these were mostly about the engine being used in hard service, like trucks.

Both the head gasket and pump weaknesses are mollified a lot when the engine is used in lower load, constant rpm service which is typical of industrial and agricultural service, which is what gave the engine a new lease on life after its failure as a truck engine. Marine service, is of course, in that same realm of operation as agricultural and industrial constant-condition use.

Interestingly this same engine also used a rotary injection pump--- its maintenance and overhaul are covered in the Ford of England Dorset diesel operation and shop manuals that came with our boat. But I have never encountered anyone with the rotary pump in a marine application and we've never discussed them with our acquaintances in the UK as we don't have them. So I have no idea if they represented any sort of advantage over the inline pump.

The inline pump is the single most expensive component on the Ford Dorset diesel. The last I heard an overhaul was about $1,000 and that was some years ago so the higher cost of labor these days has probably increased that cost.

I do not know statistically what the most common reason is for having to overhaul the pump. I was told a long time ago that plunger and bore wear was a cause as this gradually reduces the power of the injection "shots' going to the injectors and eventually this will begin to affect the engine's performance. As this kind of wear is affected by a lot of things--- how the engine is operated, fuel lubricity, and so on--- it's probably hard to impossible to attach a consistent hour number to the pump's TBO.