You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Foam Brush for Varnish

- Thread starter meridian

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Cigatoo

Guru

I’ve got some interior varnishing to do, flat finish. Getting foam brushes at hardware stores is hit or miss on quality.

Any recommendations on a good brand?

Get them from Jamestown Distributers.

https://www.jamestowndistributors.com/userportal/show_product.do?pid=1189

tiltrider1

Guru

- Joined

- Aug 2, 2017

- Messages

- 4,354

- Location

- Pacific North West

- Vessel Name

- AZZURRA

- Vessel Make

- Ocean Alexander 54

AIM Supply - I pay $8 for 48 brushes.

Bkay

Guru

- Joined

- Aug 8, 2018

- Messages

- 580

- Location

- United States

- Vessel Name

- Wingspan

- Vessel Make

- Aluminum Catamaran

I agree with David that badger hair is best. But for small areas I will use foam so I can just throw them away.

JEN foam brushes were recommended to me by some expert along the line (I can't remember who, but I've had good luck with them on small areas).

JEN foam brushes were recommended to me by some expert along the line (I can't remember who, but I've had good luck with them on small areas).

Nomad Willy

Guru

I use natural bristle brushes.

My wife usta use foam but she gave it up.

I’ll check at home to see what Rebecca Whitman says about this.

My wife usta use foam but she gave it up.

I’ll check at home to see what Rebecca Whitman says about this.

Maerin

Guru

I use natural bristle brushes.

My wife usta use foam but she gave it up.

I’ll check at home to see what Rebecca Whitman says about this.

Foam works, but if you use the box store brand, not JENN, your results will be poor. Use a wide mouth container, DON’T scrape the brush against the lip to remove excess, just press it gently against the side. With foam, don’t “brush”, just stroke. Get as much material on as quickly as you can and then let the varnish do its thing. The more you monkey with it, the worse it’ll look. That’s the hardest part of the process! Let it alone!! Long, quick, even strokes. Once you lose the wet edge, you’re done. Go back over it & you’ll for sure have a hot mess. Thin the varnish, you may need to thin as you work it. Your job is to get the varnish onto the work as evenly and quickly as you are able, the varnish does the rest!! Don’t apply when the sun is on the work or the wind is blowing. Early morning as soon as the dew is off. The slower the solvents flash off, the longer the varnish has to self level, and THAT is what makes the shine! Cool, still mornings are the stuff of which varnish dreams are made!

Giggitoni

Guru

- Joined

- Jun 21, 2008

- Messages

- 2,092

- Location

- United States

- Vessel Name

- Mahalo Moi

- Vessel Make

- 1986 Grand Banks 42 Classic

Foam works, but if you use the box store brand, not JENN, your results will be poor. Use a wide mouth container, DON’T scrape the brush against the lip to remove excess, just press it gently against the side. With foam, don’t “brush”, just stroke. Get as much material on as quickly as you can and then let the varnish do its thing. The more you monkey with it, the worse it’ll look. That’s the hardest part of the process! Let it alone!! Long, quick, even strokes. Once you lose the wet edge, you’re done. Go back over it & you’ll for sure have a hot mess. Thin the varnish, you may need to thin as you work it. Your job is to get the varnish onto the work as evenly and quickly as you are able, the varnish does the rest!! Don’t apply when the sun is on the work or the wind is blowing. Early morning as soon as the dew is off. The slower the solvents flash off, the longer the varnish has to self level, and THAT is what makes the shine! Cool, still mornings are the stuff of which varnish dreams are made!

^This!

Nomad Willy

Guru

I agree w Maerin too.

Excellent description of the details.

I'll stick w the brush though.

Excellent description of the details.

I'll stick w the brush though.

Pack Mule

TF Site Team

- Joined

- Jan 24, 2013

- Messages

- 3,749

- Location

- USA

- Vessel Name

- Slo-Poke

- Vessel Make

- Jorgensen custom 44

I also agree with Maerin. The only thing I could add is to start a foot or so out from the dry edge and stroke or pull towards the wet edge and gently lift out a little ways into the wet edge.

Last edited:

Northern Spy

Guru

- Joined

- Feb 5, 2012

- Messages

- 4,075

- Location

- Canada

- Vessel Name

- Northern Spy

- Vessel Make

- Nordic Tug 26

For me it depends on the varnish. I use decent quality high density foam brushes with Epifanes Rapidcoat and Rapidclear, but switch to brushes for the final coats of Epifanes varnish.

When I use Daly's Seafin oil, I only use a brush.

When I use Daly's Seafin oil, I only use a brush.

- Joined

- Nov 8, 2012

- Messages

- 2,315

- Location

- USA

- Vessel Name

- Sandpiper

- Vessel Make

- Bluewater 40 Pilothouse Trawler

I use a good quality bristle brush for varnish. Foam is ok on flat areas but difficult to use on details like corners.

For the final coat on interior varnish, after several coats of varnish, sanding and cleaning, I wipe the varnish on with cloth. The varnish is thinned 10 to 20 percent. I dip the cloth in the thinned varnish, squeeze out most of the varnish and wipe the it on in one direction. No brush marks.

For the final coat on interior varnish, after several coats of varnish, sanding and cleaning, I wipe the varnish on with cloth. The varnish is thinned 10 to 20 percent. I dip the cloth in the thinned varnish, squeeze out most of the varnish and wipe the it on in one direction. No brush marks.

Last edited:

- Joined

- Jan 9, 2014

- Messages

- 4,181

- Location

- USA

- Vessel Name

- N/A

- Vessel Make

- 1999 Mainship 350 Trawler

(Apologies for the hijack, but.......) Since we're diving heavy into technique. I'm working on two projects and have not worked with varnish before. With finishes like polyurethane you can finish with fine steel wool to get any imperfections and get a smooth finish.

That doesn't appear to be the case with varnish. I hit it with a fine steel wool and lost the shine immediately.

how do you get the imperfections out and get it smooth to the touch after the final coat?

That doesn't appear to be the case with varnish. I hit it with a fine steel wool and lost the shine immediately.

how do you get the imperfections out and get it smooth to the touch after the final coat?

Alaskan Sea-Duction

Guru

- Joined

- Jul 6, 2012

- Messages

- 8,061

- Location

- USA

- Vessel Name

- Alaskan Sea-Duction

- Vessel Make

- 1988 M/Y Camargue YachtFisher

Terry, I feel your pain brother!!! I have used them ALL. Hair brush seem to work the best. I have only one cap rail and it is around the cockpit. It was the nightmare from hell. Finally after 10 coats it came out shiny....Then I applied only one more and left it alone as I didn't want to screw it up. All I have to say is good luck..

My old friend was a cabinet maker. He did not own a brush. He would take a piece of wool sock the size of a golf ball and place it inside a thin nylon sock. He would hold it in his fingers with the ball in front. The wool would store the varnish and the nylon would apply it without and lint

C lectric

Guru

Foam brushes. The only ones that work are from Jenn Mfg. Use no other. I have tried MANY of them. I cannot say all but far too many that goofed up.

I have lots of varnish and it looks good, maybe not perfect but that is more me than the brush.

I now get them from Lee Valley Tools or in the US , Veritas.

The Jenns were also available through Ebay and Amazon.

I have lots of varnish and it looks good, maybe not perfect but that is more me than the brush.

I now get them from Lee Valley Tools or in the US , Veritas.

The Jenns were also available through Ebay and Amazon.

Maerin

Guru

how do you get the imperfections out and get it smooth to the touch after the final coat?

Ha! You don't!! Therein lies the rub. That's why it's called the final coat. What you get is final. There is no after the final coat, there's only another coat. If you're unhappy with the results of the final coat, that coat just became the next to last coat.

If you're looking for smooth to the touch, you may want to wet sand between coats, I use 400 grit, wet sand VERY early in the morning so you're coating before the sun gets high enough to heat the surface. Add a bit of Dawn to the water to lubricate and add a bit of degreasing quality, then clean with a wet cloth, rinse cloth, clean again, then wipe down with a clean lint free rag and denatured alcohol. Tack off a section just before coating. I cover anything that is in the sunlight until just before I tack it to keep it cool. If it gets warm, the varnish will start to flash off before it floats out...= brush marks. The varnish must have a chance to self-level. As much material as you can get on as quickly as possible and LET IT ALONE. If you are brushing to smooth out the coat, you're just chasing your tail. The varnish will smooth out the coat all by itself! Your job is to provide the optimum conditions for that to occur.

Bugs- are karma coming back to punish you for the time you were cross with your dog.

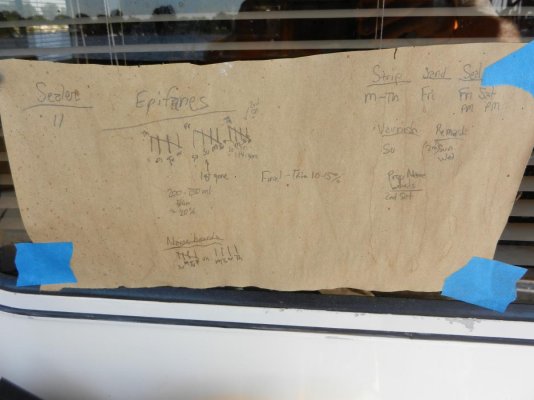

BTW, the pics are almost last coat... 2 coats CPES, 15 coats Epifanes gloss, wet sanded between coats.

Attachments

- Joined

- Nov 8, 2012

- Messages

- 2,315

- Location

- USA

- Vessel Name

- Sandpiper

- Vessel Make

- Bluewater 40 Pilothouse Trawler

how do you get the imperfections out and get it smooth to the touch after the final coat?

Read post #14 about wiping on the final coat.

Yup, Jenn. Order a big box from amazon. Great advice on mornings after things dry. If you find it getting later in the day, don’t Varnish after the point temps start to fall. Rising temps make for a better set. Learning to stop messing with it is the hardest lesson to learn.

Maerin

Guru

Maerin

That is very glossy teak! Looks great!

Thank you! I only wish it would stay that way! I'm facing the decision to get another year from a couple renewal coats or whether it's time to strip it and start over. It's starting to get pretty yellow and places are starting to loosen.

There's no getting around the relationship between good looking varnish and lots of work. They're joined at the hip!

Thank you! I only wish it would stay that way! I'm facing the decision to get another year from a couple renewal coats or whether it's time to strip it and start over. It's starting to get pretty yellow and places are starting to loosen.

There's no getting around the relationship between good looking varnish and lots of work. They're joined at the hip!

Great looking! How many years ago did you strip and apply the CPES?

I have one board on my boat that I have taken down to bare wood at least 3 times in 25 years, including this year. I don't know why this one board is so difficult to keep looking good. I get at least a couple of years from almost every other board on the boat between recoats, but this one gets a recoat every year, as it always needs it.

Whenever I see a place starting to loosen, I take the loose stuff off and build with a number of coats. I had a big zit on the cap rail this year, that I have started to repair. The rest of the rail has a build of close to 1/16" but one little spot turned black and lifted a 2" dia dome up 1/4", so off it came. It will take 10 or more coats on that one spot before it will smooth into the rest of the rail, and I am not optimistic that the colour will match. No way is that rail going down to bare wood, the rest of it is in great shape.

Maerin

Guru

The caprails were -OK- when we bought the boat in 2006, I wooded them in 2011, and they're about due for wooding again. I can probably squeak another year out of the varnish with some spot repairs, but it sure doesn't look like it did when the last refinishing was just completed!