Pete Meisinger

Guru

- Joined

- Oct 7, 2012

- Messages

- 3,145

- Location

- USA

- Vessel Name

- Best Alternative

- Vessel Make

- 36 Albin Aft Cabin

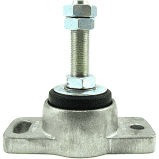

I'll try to post a picture but in case it does not work I will try a good description.

I want to align the engine on my Albin. I am not certain one of the mounts was tightened properly when we reinstalled the engine. The "up/Down" adjusters seem pretty straight forward but there does not appear to be any "Port/Starboard" adjustment screws or shafts or any of the numerous adjustment you can see on YouTube.

I suppose the mounts could be loosened from the stringers and the engine pry barred into correct alignment. The stringers are steel and in good condition. I have made some hardwood wedges in anticipation of the job to tap into position and hold the engine while I tighten the mounts.

But I don't like the idea. Am I missing something? Does anybody think I should change the mounts to some with horizontal adjusters?

pete

PS: Not having good luck with the images, I will submit this thread and work on pictures

I want to align the engine on my Albin. I am not certain one of the mounts was tightened properly when we reinstalled the engine. The "up/Down" adjusters seem pretty straight forward but there does not appear to be any "Port/Starboard" adjustment screws or shafts or any of the numerous adjustment you can see on YouTube.

I suppose the mounts could be loosened from the stringers and the engine pry barred into correct alignment. The stringers are steel and in good condition. I have made some hardwood wedges in anticipation of the job to tap into position and hold the engine while I tighten the mounts.

But I don't like the idea. Am I missing something? Does anybody think I should change the mounts to some with horizontal adjusters?

pete

PS: Not having good luck with the images, I will submit this thread and work on pictures