Lou_tribal

Guru

Hello my fellow TFers!

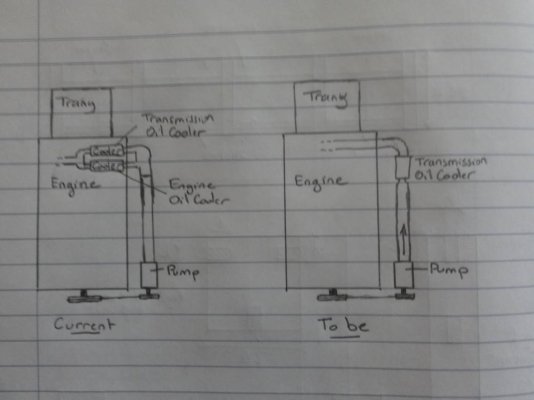

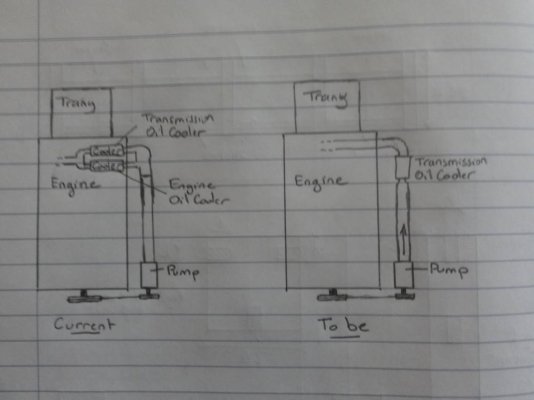

Following some events last year I am in the process of modifying my engine cooling system. In summary, I currently have an engine oil cooler as well as a tranny oil cooler. I plan to remove the engine oil cooler, there is no issue in removing it, I did many hours of test run lat year and up here in our cool weather and water an oil cooler is not needed on my engine, and even better the engine reach a better warmer temp without it.

Long story short, currently the two oil coolers are in parallel on the water line right after the raw water pump ( so first in line). By removing the engine oil cooler I will have only the tranny oil cooler in serie in the line after the pump.

I was wondering if this can cause an issue with the water flow? I do not want to create a bottleneck in he cooling line by doing his.

To illustrate this description below is a schema of what I have and what I plan to get ( sorry for the poor graphics I am not an artist lol).

Any input will be much appreciated.

Thank you!

L

Following some events last year I am in the process of modifying my engine cooling system. In summary, I currently have an engine oil cooler as well as a tranny oil cooler. I plan to remove the engine oil cooler, there is no issue in removing it, I did many hours of test run lat year and up here in our cool weather and water an oil cooler is not needed on my engine, and even better the engine reach a better warmer temp without it.

Long story short, currently the two oil coolers are in parallel on the water line right after the raw water pump ( so first in line). By removing the engine oil cooler I will have only the tranny oil cooler in serie in the line after the pump.

I was wondering if this can cause an issue with the water flow? I do not want to create a bottleneck in he cooling line by doing his.

To illustrate this description below is a schema of what I have and what I plan to get ( sorry for the poor graphics I am not an artist lol).

Any input will be much appreciated.

Thank you!

L