johnma

Guru

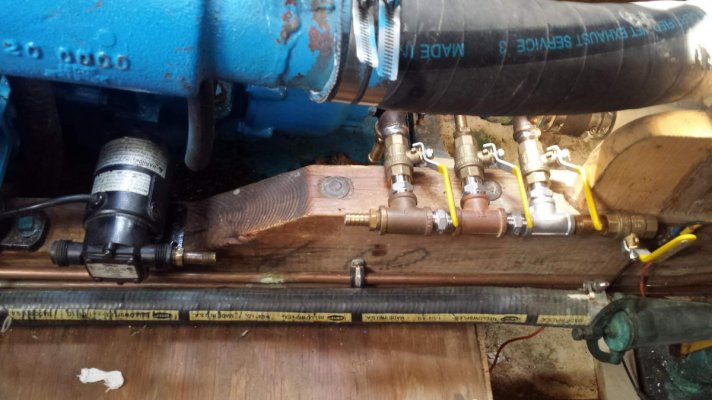

Those fittings make me very nervous. They are not fitting into the tee's properly. A proper npt fitting should screw into its mating fitting 1-1/2 to 3 turns by hand before you tighten with a wrench. You have some with the fitting almost bottomed out on one side and barely in on the other side. I would be willing to guess that you have a combination of threads here. Npt, sae, jic, bsp, and various metrics. (Japan and Germany use different metric standards as do Caterpillar, Komatsu, Hitachi and many other machine manufacturers.)

Before you hook this up you should cap off each end and put an air compressor on one side and pressurize the whole thing to 100 psi. You're liable to find yourself with a bilge full of oil or worse, a burned up engine.

Even if it holds pressure, you may someday want to sell you boat and a surveyor would have some comments on this set up.

For what its worth, You should go to a plumbing supply or better yet a hydraulic fitting company and get the proper parts.

John

Before you hook this up you should cap off each end and put an air compressor on one side and pressurize the whole thing to 100 psi. You're liable to find yourself with a bilge full of oil or worse, a burned up engine.

Even if it holds pressure, you may someday want to sell you boat and a surveyor would have some comments on this set up.

For what its worth, You should go to a plumbing supply or better yet a hydraulic fitting company and get the proper parts.

John