Points well taken. But in the KK 42 sample which we looked at, there

was water in the foam core. I have long ago discarded the exact test results. But there was far more water which was removed from the sample than would be expected from water trapped in laminates or between laminate and core. This sample was not from the boat which previously had taken over a year to dry out.

Our study was the development of instrumentation to determine state of bonds in cored hulls non destructively. My partner in our studies was one of the top NDT scientists. He designed the NDT equipment which has been used for many years by aviation, military and NASA. Our goal was to develop an in-expensive bond tester to be used by marine surveyors. Getting away from the less than scientific sounding with a phenolic hammer. The KK sample was only one of multiple samples we tested.

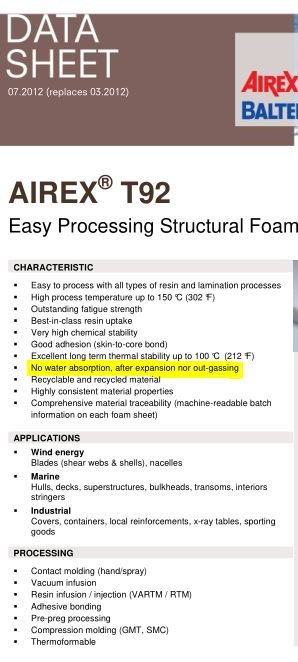

We took samples from 25 hurricane damaged hulls (destined for destruction). We developed a bond testing instrument, and did a marketing survey. The cost was in the $2,000 to $3,000 range- along with a couple of days training; -(compared to a mil spec machine which would cost in the $20,000 range). A few high end yacht builders were interested in purchase. The average commercial boat builder was not interested in scanning their hulls. The vast majority of marine surveyors were not interested. Thus the instruments were never brought to market. The bond on the KK 42 sample was also tested physically, both before drying and after. It was excellent and comparable to any other foams we had tested. The foam was destroyed before the bond was broken. I have no idea what specific foam was used in that KK 42. I might point out that the T 92 your referred to , has "Good adhesion(skin-to-corebond)" couple of bullet points above the "no water absorption".

You give a specific example of the core delamination--Was that boat subject to a freeze thaw cycle? As you pointed out, that will cause delamination . I personally owned a boat which had a cored cockpit deck which had failed due delamination of freeze thaw cycles.

An incident of a cored hull hitting a shipping container:

There are many advantages of a cored hull. I have been involved with the building of boats with cored hulls, although the ones I personally have built had solid laminates.

In 1979 I was watch captain on a 55 foot sailboat which was built of planked balsa (2 1/2 x 2 1/2 balsa coved strip plank construction), with epoxy as a glue, and aluminum nails. The hull was faired with power planes, and long boards before being glassed inside and out. I don't remember the exact laminate schedules, but there was at least 3 layers of 24 oz (with mat) roving outside and at least 2 layers of 24 oz roving on the inner layer. Standard polyester resin was used. The layup was done by Dennis Choate's company. Sometime during a 100 mile leg of the race the 55'

sailboat hit a shipping container. We were beating into 8 to 10 foot seas with 55 knots of apparent breeze, making an average of 8 knots. We had a 10 man crew, divided into 2 watches. The damage was not found until we were at our destination. No one had any recollection of a particular time we would have hit, but the boat was doing a lot of pounding. The outer laminate was completely breached by the impact point of a corner of shipping container. There was impact damage for over 2 feet in each direction .The balsa core (remember planked--not end grain) was impacted, but not breached. The inner laminate was torn loose from the balsa planking for an area of about 5 sq feet. One of our considerations in the building of further balsa stripped planked hulls was that they should tie the inner and outer laminates together. Some foam hulls have a tie between inner and outer laminates; most do not. My speculation was that many solid glass hulls might not have survived the impact.

I have not owned a KK, so I cannot address how the hull behaves in a heavy seaway. But most hulls work and distort, all be it not as much as a high end race boat (either power or sail) I have sailed on cored racing sailboats, and their hull has worked in heavy seas, when driven hard. Solid hulls work also. Some fiberglass hulls eventually fail, as the resin breaks down. (I also owned a "floppy hull": this was a solid laminate 23' sail boat made by Islander, back in the 60's--I owned the boat in the mid 80's. It was an interim boat between long distance cruising boats. I glassed in foam "forms" to give the hull stiffness. The boat was donated to Sea Scouts when I bought a larger cruising boat.)

You make a statement:

we know that FRP is very hygroscopic and absorbs water whether there is a core or not.

. I am not going to get into a debate with you about osmotic blistering, (which I have been studying since the late 1960's, including examining a number of boats in the Med, including one what eventually was destroyed). But fiberglass polyester laminate acts as a semipermeable membrane, that allows an osmotic process. Not because fiberglass polyester resin is "hygroscopic". Salt is hygroscopic it attracts moisture from its surroundings.