Lou_tribal

Guru

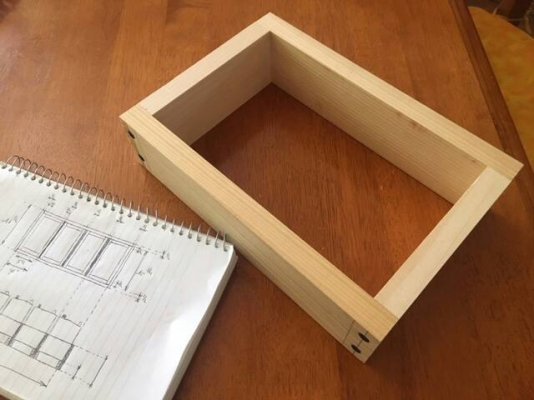

I am about to build a box for y 4 gc2 batteries.

Is it better to separate the 4 batteries within the box or is it fine to put the 4 side by side?

L

Is it better to separate the 4 batteries within the box or is it fine to put the 4 side by side?

L

. I seem to recall is was some foam-type auto gasket material that is supposed to be impervious to oil and acid. I do remember that I was looking for something that would conform to the surfaces and create a water-tight seal.

. I seem to recall is was some foam-type auto gasket material that is supposed to be impervious to oil and acid. I do remember that I was looking for something that would conform to the surfaces and create a water-tight seal.