Greetings,

Mr. rw. I just bought a small compressor to keep aboard-go figure...

Husky 3 gal. Portable Electric Oil-Lubricant Air Compressor with Combo Kit-BS1003 - The Home Depot

During our recent re-paint I had the use of a much larger machine and I brought a number of my air tools (scraper, die grinder, cut-off wheel, spray gun, spot sand blaster etc.) on board to be used during the re-refurbishments. Left the compressor behind when we moved marinas but procrastinated about taking the air tools home. Soooo....bring the tools home or buy a compressor? Hahahahaha! Stupid question right?

The above unit will not allow prolonged/continuous usage of a die grinder, for example because of the small storage tank and the larger air consumption of the grinder, but it will provide sufficient air for short usages. One has to wait for the tank to refill between "bursts" but with patience, it does the job.

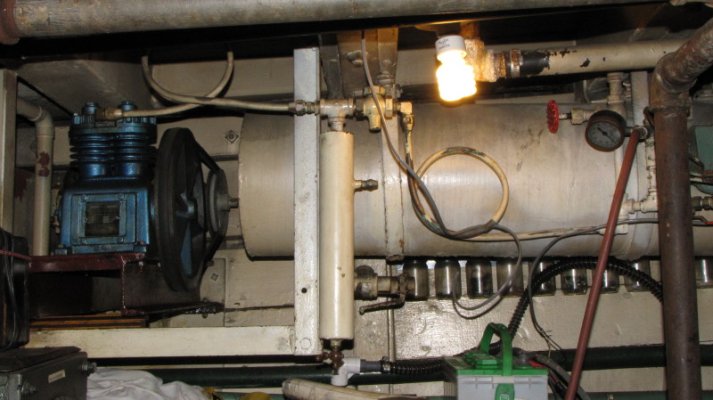

I've actually found a spot in the ER for semi-permanent placement. For total boat coverage I just have to run a longer air hose to the work site.

Comparatively speaking, air tools are cheaper than electrical and much more efficient, in most cases, than manual tools.

Being an oil unit it CANNOT be used for Hookah diving. My Hookah unit is a self contained, stand alone device.

Yes, on the air tools. That's the one thing I miss since my compressor does not have a tank. I can spray paint but my air tools are useless.

Yes, on the air tools. That's the one thing I miss since my compressor does not have a tank. I can spray paint but my air tools are useless.