Moonzy1

Senior Member

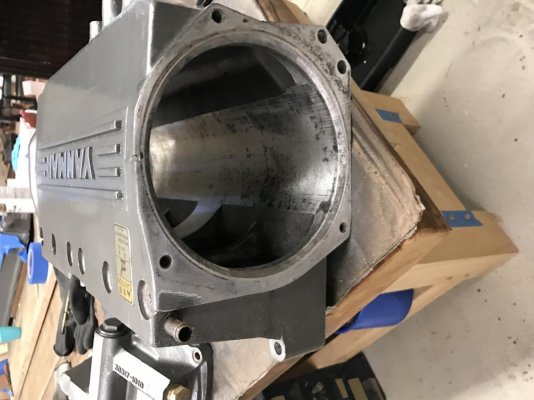

Pulled my coolers this weekend and sent the cartridges out

Kept the housings to clean myself.

To remove the black very hard gunk that is left behind on the mating surfaces of the housing and end cap...is it ok to take an orbital sander w 220 grit to it to clean it up? w light pressure

Housing is Aluminum and caps are brass I think.

Ive tried every type of solvent and doesnt get it off.

Motors are yanmar 6LYA 370's

Thank you

Kept the housings to clean myself.

To remove the black very hard gunk that is left behind on the mating surfaces of the housing and end cap...is it ok to take an orbital sander w 220 grit to it to clean it up? w light pressure

Housing is Aluminum and caps are brass I think.

Ive tried every type of solvent and doesnt get it off.

Motors are yanmar 6LYA 370's

Thank you