You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New construction: She:Kon

- Thread starter She-Kon

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

ben2go

Guru

Good to hear those tornadoes didn't touch down.We have them kind of frequently here, and they are no joke.It's a sickening helpless feeling to stand in your backyard and watch neighborhoods be completely wiped out by them.

Are you using peelply to help tame those prickly tricky edges?If no,do you think it would help?Maybe wrap a 2x in plastic food wrap,clamp it at the top,and use a weight to hold it tight at the bottom.Just a passing idear.It may need to keep on traveling by tho.

Are you using peelply to help tame those prickly tricky edges?If no,do you think it would help?Maybe wrap a 2x in plastic food wrap,clamp it at the top,and use a weight to hold it tight at the bottom.Just a passing idear.It may need to keep on traveling by tho.

She-Kon

Senior Member

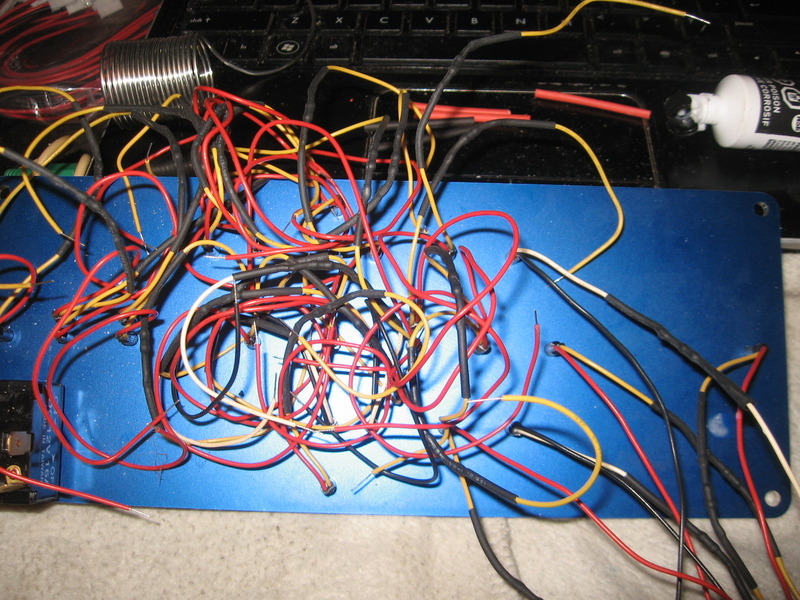

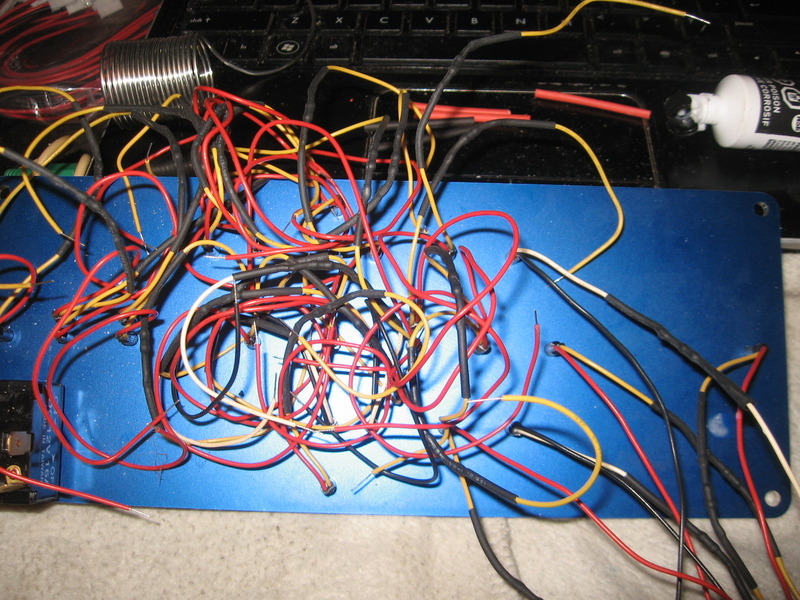

Too hot to work on the boat this afternoon so I stayed in the basement and tinkered. Tried to wrangle some tiny wires for the Mimic panel I designed.

Web log updated for a second time today! Bonus! http://she-kon.blogspot.ca/2015/09/bonu ... iring.html

http://she-kon.blogspot.ca/2015/09/bonu ... iring.html

Time for dinner. Popsicle's and ice cream!

Web log updated for a second time today! Bonus!

Time for dinner. Popsicle's and ice cream!

She-Kon

Senior Member

Are you using peelply to help tame those prickly tricky edges?If no,do you think it would help?Maybe wrap a 2x in plastic food wrap,clamp it at the top,and use a weight to hold it tight at the bottom.Just a passing idear.It may need to keep on traveling by tho.

Good idears Ben. Unfortunately wouldn't work on this stuff. It's very hmmmm? flimsy I guess is a good word. Think woven wet spaghetti and you might understand the consistency of this stuff once you get it wet. Even dry it's a beotch to control sometimes. It drapes nicely and wets out pretty good but that's about it, the rest of the time it's a PITA.

I'll hit the edges with the sander tomorrow. I knew it was gonna happen but did nuttin' about it. It'll cost me 5 mins on the sander and a piece of glass tape to fix. No biggie. You'd think I'd learn by now but nope. Dumb as a post.

Standby...

stubones99

Guru

They make a sheet rock sander kit that sucks up most of the dust, and that works fairly well as long as you don't use the big vacuum hose, since it does not bend very easily.

Marshalltown Vacuum Sander with 6 ft. Hose-VS792 - The Home Depot

Marshalltown Vacuum Sander with 6 ft. Hose-VS792 - The Home Depot

BruceK

Moderator Emeritus

- Joined

- Oct 31, 2011

- Messages

- 13,347

- Vessel Name

- Sojourn

- Vessel Make

- Integrity 386

A TENS (Transcutaneous electrical nerve stimulator) unit is a battery powered small box unit you wear, with adhesive on skin electrodes, said to to interfere with/reduce normal pain transmission. Not expensive, they were popular during the RSI (repetitive strain injury) epidemic of the 1980s, and were also used in back pain.

Some complaints of RSI were doubtfully organically based, eg. complaints of symptoms with no objective signs. Unfortunately for you, yours sounds very objective. Maybe talk to a specialist hand surgeon. Perhaps your advice so far is to stop doing what is causing it, I can`t see you following that while your project needs work.

Some complaints of RSI were doubtfully organically based, eg. complaints of symptoms with no objective signs. Unfortunately for you, yours sounds very objective. Maybe talk to a specialist hand surgeon. Perhaps your advice so far is to stop doing what is causing it, I can`t see you following that while your project needs work.

She-Kon

Senior Member

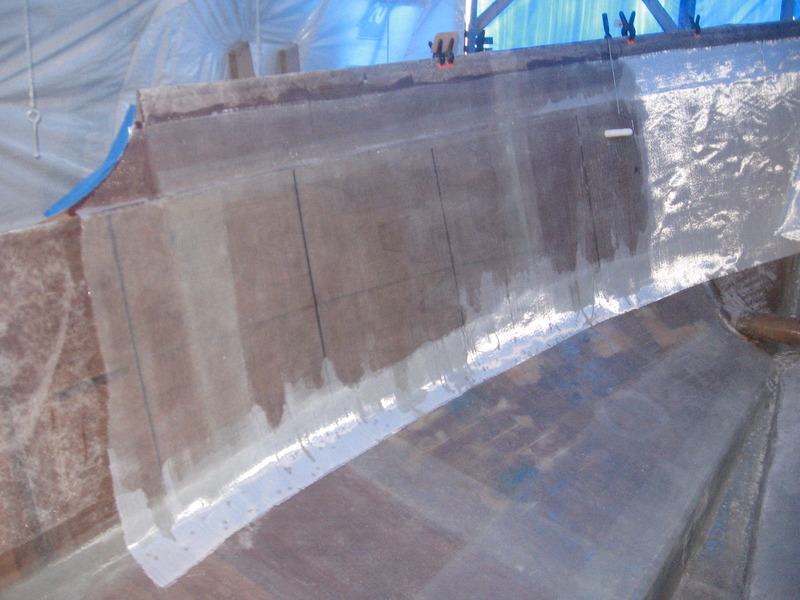

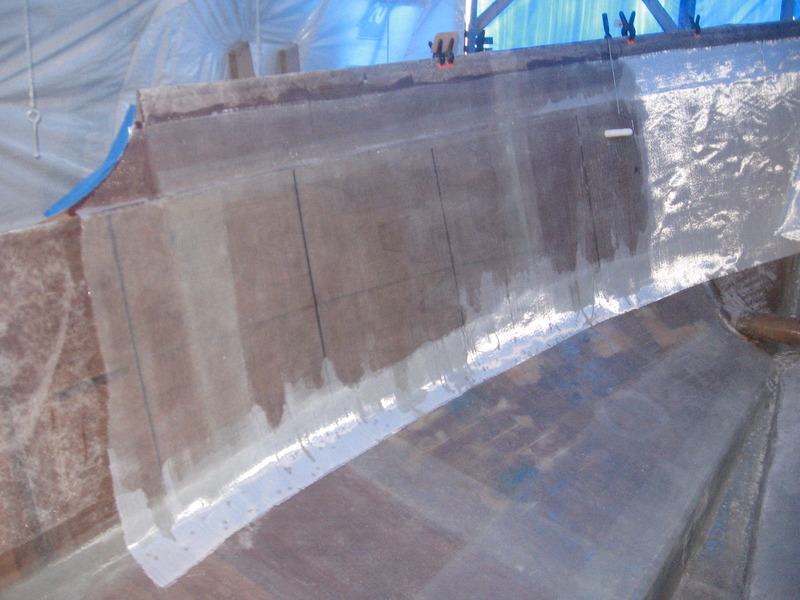

Hit the shed early and got the stbd side ready for more glass. A lil' sanding on the tape edges and then laid out the glass & gooped it down. About 3 hrs total and 1-1/2 gallons of epoxy. Nice 'n neat, quick 'n dirty. Got out of the shed before the heat started to build.

Couple more pics on the blog updated: http://she-kon.blogspot.ca/2015/09/star ... layer.html

Tomorrow I'll do a lil' sanding on the stbd bow then lay out the 10 oz finishing cloth. That should go pretty quick too!

Standby....

Couple more pics on the blog updated: http://she-kon.blogspot.ca/2015/09/star ... layer.html

Tomorrow I'll do a lil' sanding on the stbd bow then lay out the 10 oz finishing cloth. That should go pretty quick too!

Standby....

ben2go

Guru

I understand now about trying to brace(?) the glass until it cures.A big jig and rotisserie would have been handy on this build.You could have positioned the hull where all the lay ups were down and aided by gravity.I'm not 100% sure how one would go about jigging a new build into a rotisserie tho.I've seen small,under 20feet,glass boats put on a homemade rotisserie.

Here's a DIY auto type using engine stands.Pretty sure it's only good for about 1500lbs.

Here's a DIY auto type using engine stands.Pretty sure it's only good for about 1500lbs.

She-Kon

Senior Member

Don't think for a minute I didn't consider that Ben! I don't think I would have had enough room though. Pretty tight in there!

I was in a shipyard a few years ago where they build all kinds of utility, Fire/rescue and workboats. All in aluminum. They range from 30 to 65 feet or so and are all built on rotisseries so the welders don't have to weld vertical or overhead. Quite the operation!

I was in a shipyard a few years ago where they build all kinds of utility, Fire/rescue and workboats. All in aluminum. They range from 30 to 65 feet or so and are all built on rotisseries so the welders don't have to weld vertical or overhead. Quite the operation!

Crusty Chief

Guru

Rick,

After you are done glassing the hull, what do you think the final thickness will be? Will it be thicker below the waterline or same throughout?

Cheers!

After you are done glassing the hull, what do you think the final thickness will be? Will it be thicker below the waterline or same throughout?

Cheers!

She-Kon

Senior Member

Hi J&TRick,

After you are done glassing the hull, what do you think the final thickness will be? Will it be thicker below the waterline or same throughout?

It's a wee bit thicker on the bottom where I used a 33 oz triaxial fiberglass plus the 12 oz.

Working from the inside out on the bottom & assuming a 50/50 glass to resin mix it'd be something like:

10 oz cloth is .017"

12 oz 0/90 is about 0.023"

1708 is 0.029"

1/2" Meranti BS1088 plywood

33 oz triax wetted out is about 0.050"

12 oz 0/90 wetted out is about 0.023"

So total would be somewhere around 0.142" which is something like 9/64". Including the 1/2" core that's a total of 21/32" or 0.640"

The sides are double the inside bottom plus 1/2" core so that's about 0.059" a little over 9/16" thick.

I haven't cut any holes in the hull yet but I'll be able to measure it then.

Doesn't sound like much does it?

The bow area and keel bottom also have an extra layer of multiaxial carbon fiber (Saertex) which I think was 22 oz/yd and probably about 0.035" thick

The transom has 20 oz basalt fabric, 1708 and 9 oz satin weave outside. It has a 1" core and inside will get 1708 plus 12 oz 0/90 and 10 oz plain weave.

All of the seams have at least 4 layers of 6 oz tape plus double the fabric overlapped. I wouldn't even venture a guess how thick they are!

Last edited:

RT Firefly

Enigma

Greetings,

Mr. SK. I've been following this thread and marveling at your skill and tenacity. If you hadn't answered so soon I would have guessed your hull was going to be about 10" thick! As it is, she should be a strong but relatively light craft.

Mr. SK. I've been following this thread and marveling at your skill and tenacity. If you hadn't answered so soon I would have guessed your hull was going to be about 10" thick! As it is, she should be a strong but relatively light craft.

She-Kon

Senior Member

.... As it is, she should be a strong but relatively light craft.

Oh Thank Gawd! I don't think I can afford to put anymore epoxy & fiberglass into this pig!

Crusty Chief

Guru

Rick,

It's about what I thought it would be. Your use of the carbon fiber is gonna make it a lot stronger than regular weave. And you will most likely build up areas for the thru hulls, bulkheads and such also. Keep at it bud, your making progress.

It's about what I thought it would be. Your use of the carbon fiber is gonna make it a lot stronger than regular weave. And you will most likely build up areas for the thru hulls, bulkheads and such also. Keep at it bud, your making progress.

She-Kon

Senior Member

Rick,

It's about what I thought it would be. Your use of the carbon fiber is gonna make it a lot stronger than regular weave. And you will most likely build up areas for the thru hulls, bulkheads and such also. Keep at it bud, your making progress.

On ole' timer once told me: 'You only realize you're making progress when you start cutting holes in that nice hull you've built!'

The carbon fiber will come in handy if we run into any more submerged picnic tables on the river. Plenty of junk gets washed down the ole' St. Lawrence river especially in the spring. I wish I had more of it but at somewhere around $100 USD sq/yd it was way out of my budget envelope!

She-Kon

Senior Member

Took advantage of much cooler weather today and spent a total of 7 hours sanding the inside of the boat in prep for the next layers of glass.

Sanded from stem to stern and keel bottom to bulwarks. Almost got it all done, just about a half hour left then I'll lay out the glass in the keel tomorrow and get that glued in. I don't have enough epoxy to finish the inside of the boat this year but if I skip the finishing layer for now I'll be able to get the stringers in before I have to call it quits for the year.

More pics and more of me whining on today's web blog updated: http://she-kon.blogspot.ca/2015/09/long ... -shed.html

Standby....

Sanded from stem to stern and keel bottom to bulwarks. Almost got it all done, just about a half hour left then I'll lay out the glass in the keel tomorrow and get that glued in. I don't have enough epoxy to finish the inside of the boat this year but if I skip the finishing layer for now I'll be able to get the stringers in before I have to call it quits for the year.

More pics and more of me whining on today's web blog updated: http://she-kon.blogspot.ca/2015/09/long ... -shed.html

Standby....

She-Kon

Senior Member

Box keel port side & bottom glassed & gooped!

Man I'll be happy when I don't have to stick my head in there ever again!

I says; "Honey! I dropped a wrench in the bilge again!"

She says; "No friggin' way, not this time HONEY my ass. Go fish it out your own dam self!"

I says; "Hard to get good crew anymore!"

Web log updated: http://she-kon.blogspot.ca/2015/09/keel ... layer.html

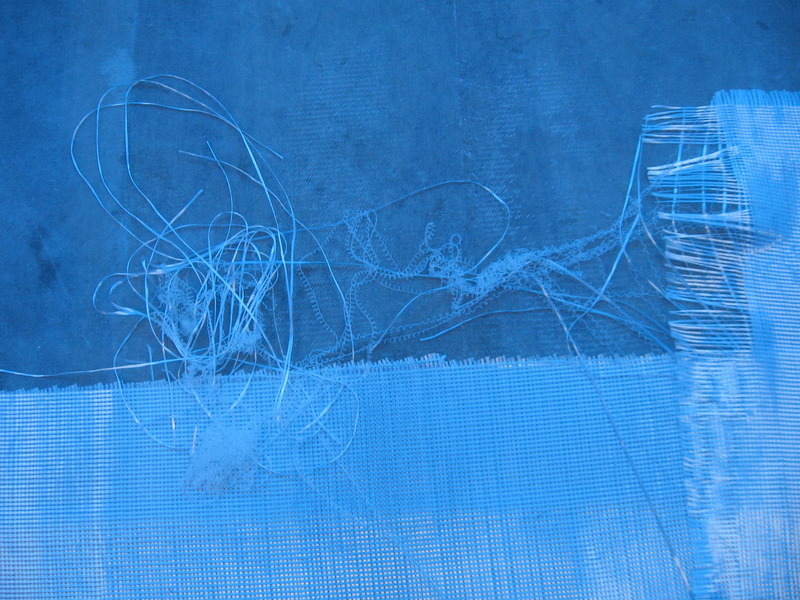

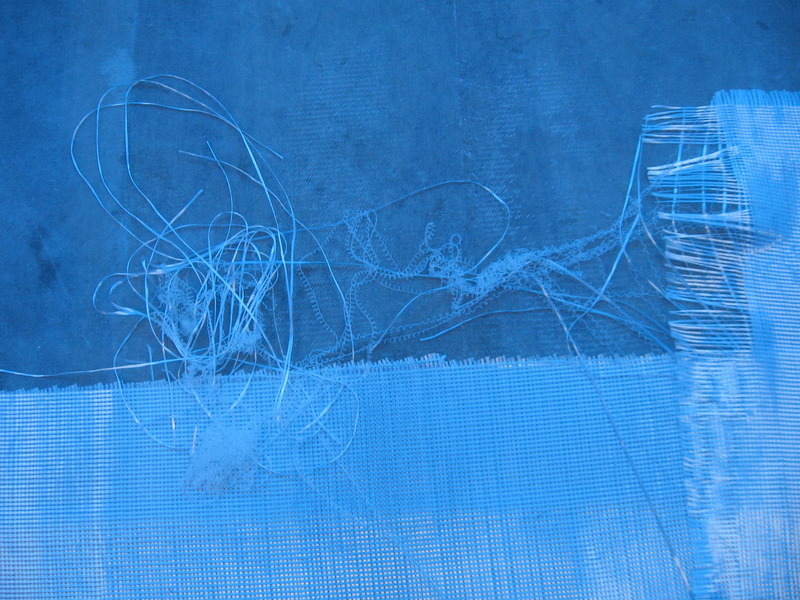

This one's for Ben. When I was telling you this 12 oz stuff was like wet spaghetti? Well this is what happens to it if you catch even one little binding thread!

One great big friggin' mess!

Man I'll be happy when I don't have to stick my head in there ever again!

I says; "Honey! I dropped a wrench in the bilge again!"

She says; "No friggin' way, not this time HONEY my ass. Go fish it out your own dam self!"

I says; "Hard to get good crew anymore!"

Web log updated: http://she-kon.blogspot.ca/2015/09/keel ... layer.html

This one's for Ben. When I was telling you this 12 oz stuff was like wet spaghetti? Well this is what happens to it if you catch even one little binding thread!

One great big friggin' mess!

She-Kon

Senior Member

She is moving forward thanks to all of your hard work!! Yea- that epoxy sounds very expensive!!

Thnx Forky. Appreciate the kind words.

I'd say all in, shipping, handling & taxes etc. I pay about $70 Cdn/gallon. If our dollar was a lil' stronger against the greenback I can get that down to $55/gal. I get my stuff from FLA. If I try to get epoxy here in the quantities I need I end up paying the thieves ab (chandlers) out $115/gallon.

She-Kon

Senior Member

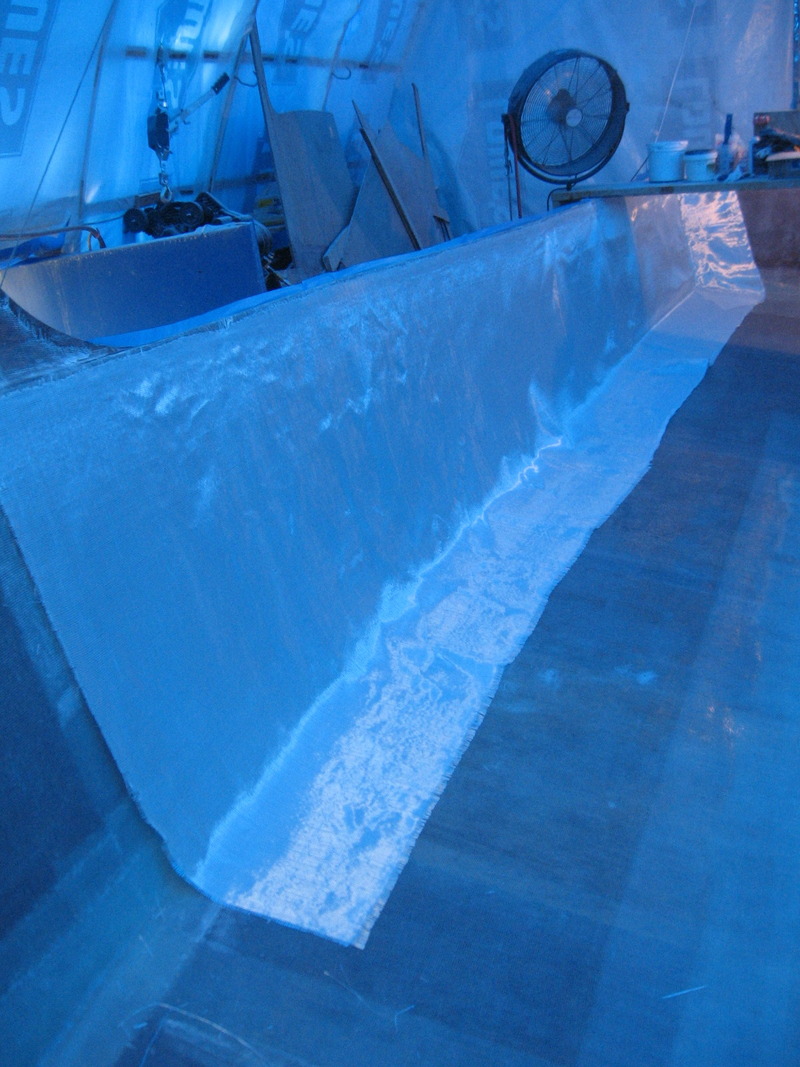

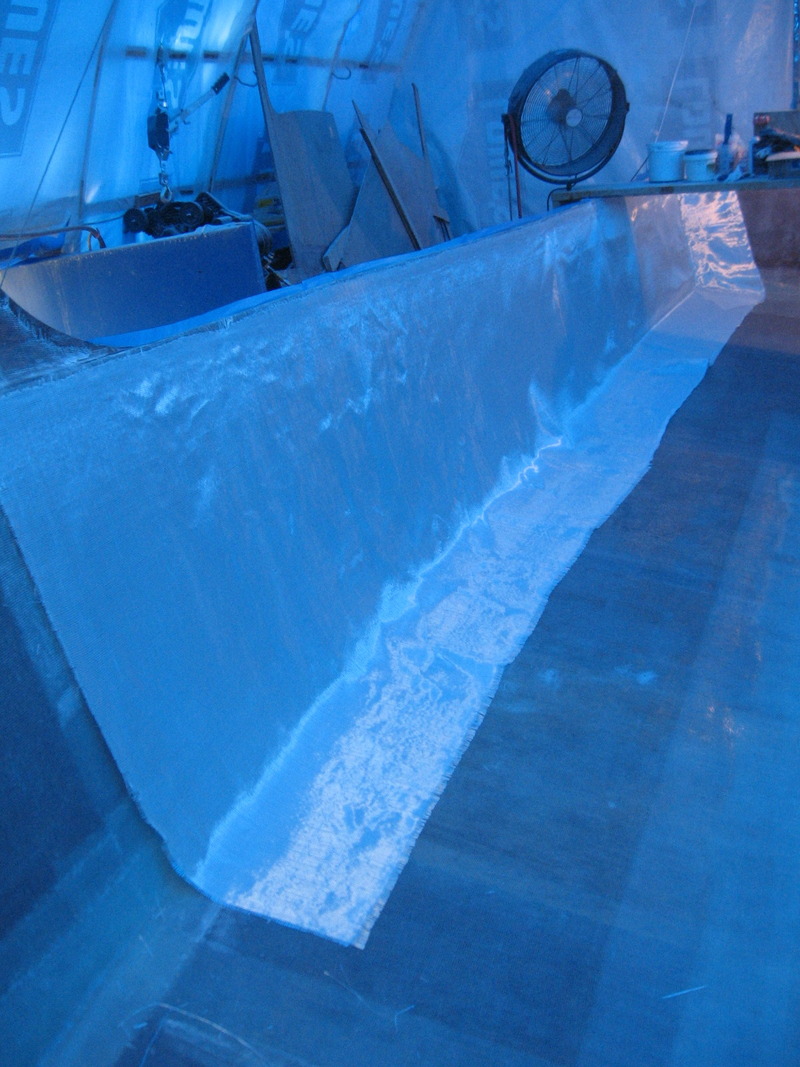

Another good day in the boat shed. Started about 09:00 and cleaned up the fabric edges from the keel work day before yesterday. I played hookie from the boat shed yesterday. Sanded, vacuumed, wiped & laid out the fabric and it was lunch time. After a wee break got back to it. By 14:30 I was done.

Used about 1-3/4 gallons of epoxy to wet out that strip which is about 28' long by 4' wide. Sort of found my rhythm though working with this stuff. Tomorrow the port sides. I'm not 100% positive I have enough 12 oz glass left. *fingers crossed.

Web log updated with more pics. http://she-kon.blogspot.ca/2015/09/port ... layer.html

Standby...

Used about 1-3/4 gallons of epoxy to wet out that strip which is about 28' long by 4' wide. Sort of found my rhythm though working with this stuff. Tomorrow the port sides. I'm not 100% positive I have enough 12 oz glass left. *fingers crossed.

Web log updated with more pics. http://she-kon.blogspot.ca/2015/09/port ... layer.html

Standby...

siestakey

Guru

- Joined

- Jul 7, 2013

- Messages

- 1,815

- Location

- USA

- Vessel Name

- Steppin Stone IV

- Vessel Make

- Marine Trader Kelly Trawler 46

Thanks siestakey. Appreciate the kind words.

Tens unit? Is that like a wrist brace? I wear them every night. Seems to help a bit.

I am not sure of this brand I will ask my wife about what brand is best

The project is looking great

TENS EMS Unit – TENS Muscle Stimulator – EMS TENS Units

She-Kon

Senior Member

So Rick,you're closing in on laying in stringers.Tell me about those, and when you expect to start on them.I know winter is closing in fast for you.

I dunno. Thinking this weekend maybe. I have to rip some plywood but it's been raining so I can't get the table saw outside to do it.

Winter?

She-Kon

Senior Member

Port side second layer laid down and gooped!

That lil' piece of fiberglass is 15' 6" long and 4' wide! It sucked up almost exactly 1 gallon of epoxy. I'm getting better at my squeegee technique.

I usually mix 1 pt of epoxy at a time but decided to give mixing a quart a shot today. It's nice and mild out, low 70's so I knew there was little chance of it kicking off in the bucket. It worked pretty well. Fewer runs to the sticky stuff machine.

That's two quarts on and two to go.

After about an hour and 20 minutes it's all glued down. The step in the hull where the bulwarks join the hull sides is a real PITA. The wetted out glass wants to slide down the side of the hull and this leaves a 'bridge bubble' in its wake.

I'll be on bubble watch for a few hours till the epoxy decides it wants to hold everything in place! PITA!

So the big question of the day is: Do I have 'nuff 12 oz to do the rest of the port side?

Hmmm? Well I dunno yet. We'll find out soon enough!

Standby....

That lil' piece of fiberglass is 15' 6" long and 4' wide! It sucked up almost exactly 1 gallon of epoxy. I'm getting better at my squeegee technique.

I usually mix 1 pt of epoxy at a time but decided to give mixing a quart a shot today. It's nice and mild out, low 70's so I knew there was little chance of it kicking off in the bucket. It worked pretty well. Fewer runs to the sticky stuff machine.

That's two quarts on and two to go.

After about an hour and 20 minutes it's all glued down. The step in the hull where the bulwarks join the hull sides is a real PITA. The wetted out glass wants to slide down the side of the hull and this leaves a 'bridge bubble' in its wake.

I'll be on bubble watch for a few hours till the epoxy decides it wants to hold everything in place! PITA!

So the big question of the day is: Do I have 'nuff 12 oz to do the rest of the port side?

Hmmm? Well I dunno yet. We'll find out soon enough!

Standby....

She-Kon

Senior Member

Yet another big bite outta this whale!

I smell bad. Shower time. There's some more pics & stuff on the blog update: M/V She:Kon: Port sides aft

Standby....

I smell bad. Shower time. There's some more pics & stuff on the blog update: M/V She:Kon: Port sides aft

Standby....

She-Kon

Senior Member

Spent half of yesterday and a lil' more than half today in the shed sanding. Still have to get glass on the transom, back end of the box keel and the bow ahead of the thruster tube. Lots of overlapped fabric edges to be feathered out. I want to put an extra layer of tape along the bottom/keel join. The bottom fabrics weren't wide enough to overlap the sides and the bottom/keel join at the same time. Think I have 'nuff epoxy & off cuts left to get an extra layer of glass on the keel sides and bottom.

Got my butt firmly wedged between the thruster tube & stem to get that pic! Pretty cool I thought!

Few more pics on today's blog updated: http://she-kon.blogspot.ca/2015/09/coup ... -days.html

Cheers!

Got my butt firmly wedged between the thruster tube & stem to get that pic! Pretty cool I thought!

Few more pics on today's blog updated: http://she-kon.blogspot.ca/2015/09/coup ... -days.html

Cheers!

Similar threads

- Replies

- 1

- Views

- 470

- Replies

- 3

- Views

- 751

- Replies

- 14

- Views

- 806