You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hendo's Randall 35 Cray Boat complete rebuild, Perth, Western Australia

- Thread starter Hendo78

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

RT Firefly

Enigma

Greetings,

Mr. H. Oooohhhh. That’s purty

...

Mr. H. Oooohhhh. That’s purty

...

Greetings,

Mr. H. Oooohhhh. That’s purty

...

It is hard to get the wiring behind the helm looking nice but in the engine room it’s achievable with some planning and time.

Lou_tribal

Guru

Nicely done!

One thing I would be careful with is the starter cable that goes on a bracket nut in the middle of the pic, the nut may cause chaffing on the wire (I am obsessed with chaffing lol)

L

One thing I would be careful with is the starter cable that goes on a bracket nut in the middle of the pic, the nut may cause chaffing on the wire (I am obsessed with chaffing lol)

L

Nicely done!

One thing I would be careful with is the starter cable that goes on a bracket nut in the middle of the pic, the nut may cause chaffing on the wire (I am obsessed with chaffing lol)

L

Roger

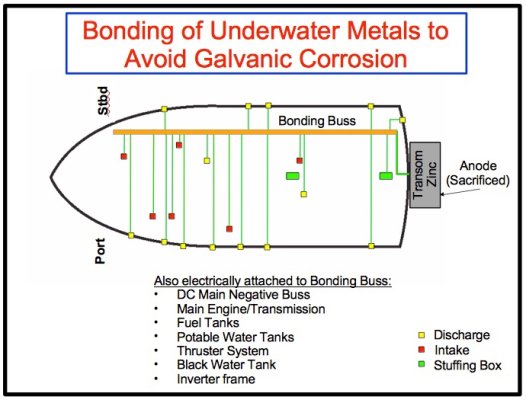

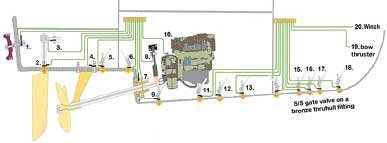

Are your seacocks stainless steel? Hope you have a GOOD bonding and sacrificial anode plan. Lot to be said for a traditional bronze seacock bolted to the hull.

Ted

Yep all 316 stainless mate. Those two are for the toilet water intake and Holding tank macerater pump.

Haven’t thought about bonding yet. By that do you mean earthing the stainless?

ben2go

Guru

Well no sanding today. I decided to continue on with the wiring. I was able to get the wiring at the alternator, the starter motor and the injector pump sorted. Have to do the same to the coolant temp and oil pressure then run it up to the helm gauges.

View attachment 77476

View attachment 77477

It is hard to get the wiring behind the helm looking nice but in the engine room it’s achievable with some planning and time.

Very nice wiring work. I know what you mean about planning and patience. I become impatient when I do wiring work and have to take many breaks to keep frustration from getting the best of me.

Very nice wiring work. I know what you mean about planning and patience. I become impatient when I do wiring work and have to take many breaks to keep frustration from getting the best of me.

Lol hearing ya mate.

Something I learned today

https://www.proboat.com/2015/04/the-mysteries-of-bonding-systems-revealed/

https://www.proboat.com/2015/04/the-mysteries-of-bonding-systems-revealed/

Something I learned today

https://www.proboat.com/2015/04/the-mysteries-of-bonding-systems-revealed/

Hey Matt, my bud...

TY for the link. I've read so many similar reports and am always ready to read another. The need for anodes to protect diode metals on boats is paramount for continued good condition of nearly all metal parts aboard.

This summer it is time for me to change all of mine, again. Luckily we dock and play in completely fresh water. Makes electric current harm to metals much, much less active than in saltwater.

Cheers!

Art

Hey Matt, my bud...

TY for the link. I've read so many similar reports and am always ready to read another. The need for anodes to protect diode metals on boats is paramount for continued good condition of nearly all metal parts aboard.

This summer it is time for me to change all of mine, again. Luckily we dock and play in completely fresh water. Makes electric current harm to metals much, much less active than in saltwater.

Cheers!

Art

Hey mate.

Just so I am clear, the anodes just aren’t bolted to the boat they are wired to as well yeh?

Hey mate.

Just so I am clear, the anodes just aren’t bolted to the boat they are wired to as well yeh?

Well, my friend... this is a big subject... I hope this helps your understanding!!!

I suggest you carefully go over link you posted as well as other marine "metal protection" reviews on the net. Many threads/posts/review-links are on TF too. Search feature: Using the words "anode, "diode", "galvanization", "corrosion", "crevice" and others similar should give you much to read.

There are a bunch of what ifs and should bes and could bes and may bes [get my drift - lol] in the marine industry regarding who thinks what about best methods for metal protection. The way I see it, and what has stood me in good metal protection capability for decades, is similar to the following sector that is in the review you posted a link to.

That is: Very carefully again review the following sector from the link...

"Design: What Does a Bonding System Do?"

Especially think about what these end portion quotes from that sector mean [underlines, italics and bolding are mine]:

"While this interconnection method works well, it has limitations. One of the most misunderstood of these is the distance over which an anode can provide protection. Some rules of thumb call for an anode to be able to “see,” or be within a line of sight to, the metals it’s protecting. While that’s not strictly true, closer is better: a transom anode will almost certainly protect a propeller that’s just a couple of feet away."

"Perhaps the most misunderstood case involves anodes found within the cooling systems of engines, generators, and other heat exchangers. These anodes are sized and designed to protect only these components. They cannot protect underwater metals and, more importantly, hull anodes cannot protect gear filled with raw water within the vessel. Protected metals must reside in the same “body of water” as the anode."

I repeat!! "Protected metals must reside in the same “body of water” as the anode."

I follow that rule.

Last edited:

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,880

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

Yep all 316 stainless mate. Those two are for the toilet water intake and Holding tank macerater pump.

Haven’t thought about bonding yet. By that do you mean earthing the stainless?

Think about your propeller shaft without a electrically bounded anode, it will pit and deteriorate as it becomes sacrificial. If I were going to use a stainless seacock, the 2 would be bonded, and the intake would have a tee with a large pencil anode. Bonding to a common anode is a good idea, but requires regular inspections. If the bonding corrodes, electrolysis begins quickly. This is an area where you can't afford a failure.

Ted

OldDan1943

Guru

- Joined

- Oct 2, 2017

- Messages

- 10,599

- Location

- USA

- Vessel Name

- Kinja

- Vessel Make

- American Tug 34 #116 2008

I'll bet you'll be very happy when you get the wiring completed.

This afternoon at HMAS Hendo the gauges came to life for the first time. Not sure why the oils pressure light is brighter. Could be a different bulb. I’ll sus out putting little LED’s in there if possible. Tomorrow I’ll connect the sender units to the gauges then tidy up the wiring then move on to the electrical binding of the metal fittings.

RT Firefly

Enigma

Greetings,

Mr. H. You might consider red gauge back lighting at some point...

Mr. H. You might consider red gauge back lighting at some point...

Kit_L

Senior Member

- Joined

- Mar 12, 2016

- Messages

- 476

- Location

- Australia

- Vessel Name

- Suu Kyi

- Vessel Make

- Custom 40' catamaran

Greetings,

Mr. H. You might consider red gauge back lighting at some point...

The first night training exercise I did with Marine Rescue here taught me that: no light from the instrument panel is welcome when you are coming in over a bar at night. Dimmable guage lighting at the very least. On the MR vessels, all console lights are dimmable (except for the anchor control panel which we cover up), and red dim lighting in the cabin is the norm at night.

Well, my friend... this is a big subject... I hope this helps your understanding!!!

I suggest you carefully go over link you posted as well as other marine "metal protection" reviews on the net. Many threads/posts/review-links are on TF too. Search feature: Using the words "anode, "diode", "galvanization", "corrosion", "crevice" and others similar should give you much to read.

There are a bunch of what ifs and should bes and could bes and may bes [get my drift - lol] in the marine industry regarding who thinks what about best methods for metal protection. The way I see it, and what has stood me in good metal protection capability for decades, is similar to the following sector that is in the review you posted a link to.

That is: Very carefully again review the following sector from the link...

"Design: What Does a Bonding System Do?"

Especially think about what these end portion quotes from that sector mean [underlines, italics and bolding are mine]:

"While this interconnection method works well, it has limitations. One of the most misunderstood of these is the distance over which an anode can provide protection. Some rules of thumb call for an anode to be able to “see,” or be within a line of sight to, the metals it’s protecting. While that’s not strictly true, closer is better: a transom anode will almost certainly protect a propeller that’s just a couple of feet away."

"Perhaps the most misunderstood case involves anodes found within the cooling systems of engines, generators, and other heat exchangers. These anodes are sized and designed to protect only these components. They cannot protect underwater metals and, more importantly, hull anodes cannot protect gear filled with raw water within the vessel. Protected metals must reside in the same “body of water” as the anode."

I repeat!! "Protected metals must reside in the same “body of water” as the anode."

I follow that rule.

Thanks mate.

Think about your propeller shaft without a electrically bounded anode, it will pit and deteriorate as it becomes sacrificial. If I were going to use a stainless seacock, the 2 would be bonded, and the intake would have a tee with a large pencil anode. Bonding to a common anode is a good idea, but requires regular inspections. If the bonding corrodes, electrolysis begins quickly. This is an area where you can't afford a failure.

Ted

Thanks Mate.

I'll bet you'll be very happy when you get the wiring completed.

Mate I’m actually really enjoying this electrical work atm. I’m learning heaps and it’s really fun seeing things come to life.

Greetings,

Mr. H. You might consider red gauge back lighting at some point...

Yeah I’ll go red like my compass mate

The first night training exercise I did with Marine Rescue here taught me that: no light from the instrument panel is welcome when you are coming in over a bar at night. Dimmable guage lighting at the very least. On the MR vessels, all console lights are dimmable (except for the anchor control panel which we cover up), and red dim lighting in the cabin is the norm at night.

Thanks for the tip mate

OldDan1943

Guru

- Joined

- Oct 2, 2017

- Messages

- 10,599

- Location

- USA

- Vessel Name

- Kinja

- Vessel Make

- American Tug 34 #116 2008

Hendo, all the instruments are powered by the same 'block'?

MAYBE, you should consider rechecking the connections and wire runs.

Barring that possibility of a large bulb, it may very well be an electric 'situation'.

Because they are all DC bulbs, you wont need a fancy dimmer. A single, common rheostat will do perfectly.

MAYBE, you should consider rechecking the connections and wire runs.

Barring that possibility of a large bulb, it may very well be an electric 'situation'.

Because they are all DC bulbs, you wont need a fancy dimmer. A single, common rheostat will do perfectly.

OldDan1943

Guru

- Joined

- Oct 2, 2017

- Messages

- 10,599

- Location

- USA

- Vessel Name

- Kinja

- Vessel Make

- American Tug 34 #116 2008

Are your seacocks stainless steel? Hope you have a GOOD bonding and sacrificial anode plan. Lot to be said for a traditional bronze seacock bolted to the hull.

Ted

My AT came with the special plastic hull valves. They may be good but I was still uncomfortable with them. Had them all changed to bronze and bonded. I had them up the size for the generator and A/C. Less chance of them fouling.

Hendo, all the instruments are powered by the same 'block'?

MAYBE, you should consider rechecking the connections and wire runs.

Barring that possibility of a large bulb, it may very well be an electric 'situation'.

Because they are all DC bulbs, you wont need a fancy dimmer. A single, common rheostat will do perfectly.

You referring to the brighter light on the oil pressure gauge?

OldDan1943

Guru

- Joined

- Oct 2, 2017

- Messages

- 10,599

- Location

- USA

- Vessel Name

- Kinja

- Vessel Make

- American Tug 34 #116 2008

You referring to the brighter light on the oil pressure gauge?

Yes. Just a guess.

Similar threads

- Replies

- 21

- Views

- 4K

- Replies

- 49

- Views

- 11K