The mad scientist

Who's lost weight!

The mad scientist

The mad scientist

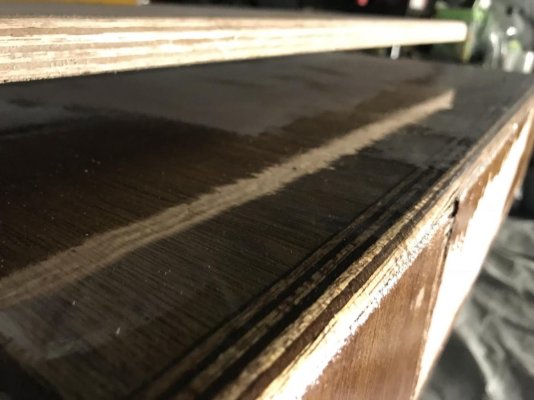

Right so earthing the driveshaft. I was thinking of using a braided flat cable like this wrapped around the shaft and have the earth cable attached to one end. What’s your thoughts on this? Dumb idea?

View attachment 75037

View attachment 75038

View attachment 75039

Sorry, you are too young to own that boat. LOL

Ah ha, wife got fed up with you and threw you out of the house? That will motivate you to work faster. LOL

My shafts have a piece of spring steel (flat) with a brush on the end connected to the grounding system.

Here you go

L

Here you go

L

Haha I’m getting in early. I spent most of my 30’s building this. I’m 40 this year and plan to enjoy using it.

Hahaha what?

What a change a few Thousand posts can make. She is looking Great. I’ve enjoyed the trip so far and look forward to your next update.

I am not now nor have I ever been a carpenter, shipwright nor cabinet maker. In fact, I dont pay any of those on TV either. Permit me to make one observation. Remember you may need access to things between the back of the cabinets without disassembling the boat. My Nordhavn was a prime example of 'hidden stuff'. The first owner put a 20KW generator in the aft starboard part to the ER. IF anything needed to be repaired outboard of the gen, it would have involved cutting a hole in the hull. There were no organized wire ways.... I cannot tell you how many 'extra wires' I pulled out over the years not how many pounds of wire ties I pulled out.

On my AT, they used PVC (?) pipe as wire ways, neat and orderly.... fantastic. You may consider cutting panel openings in the back of the cabinets now for access to that space between the cabinet and the hull.

ALSO, draw up the wire diagram and a separated piping diagram. Tag the wires at both ends so they can be identified. All those red, black, white, yellow and green wires all look a like. Document, document, document now, while it is easy. You are putting a herculean efforts in your rebuild. This boat will be around long after your 'final voyage' soooooo, make it easy on the next owner(s). Yea yea, we all know, such documentation may not 'follow' the boat beyond the next owner but, you tried. You might consider 2 copies, one for onboard and one at the house. That way, you wont forget and leave it at home. I hope you can drawer better than I can. Let's just say, my drawings are rather "artistic".

At one final 'observation'. Just because you have the boat leveled on the blocks does not mean the 'in the water' level will be the same. Dont ask me how I know, please.