JDCAVE

Guru

- Joined

- Apr 3, 2011

- Messages

- 2,910

- Location

- Canada

- Vessel Name

- Phoenix Hunter

- Vessel Make

- Kadey Krogen 42 (1985)

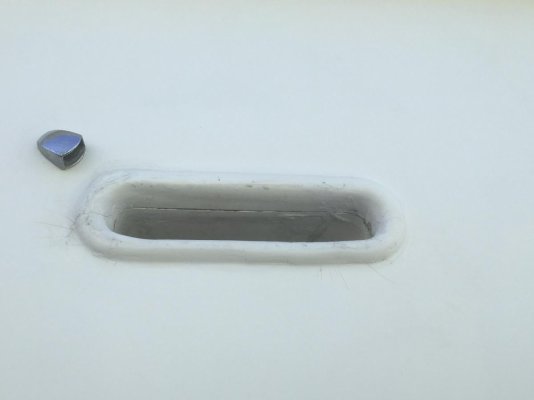

I’ve got one scupper, on the port side-deck near the entry door that has a significant crack on the upper surface and crazing where it joins to the hull. Has anyone have experience with this issue?

I wonder if it is related to lifting the boat out of the water. I notice there is some flex when the boat is removed and replaced into the water.

Jim

I wonder if it is related to lifting the boat out of the water. I notice there is some flex when the boat is removed and replaced into the water.

Jim