JDCAVE

Guru

- Joined

- Apr 3, 2011

- Messages

- 2,908

- Location

- Canada

- Vessel Name

- Phoenix Hunter

- Vessel Make

- Kadey Krogen 42 (1985)

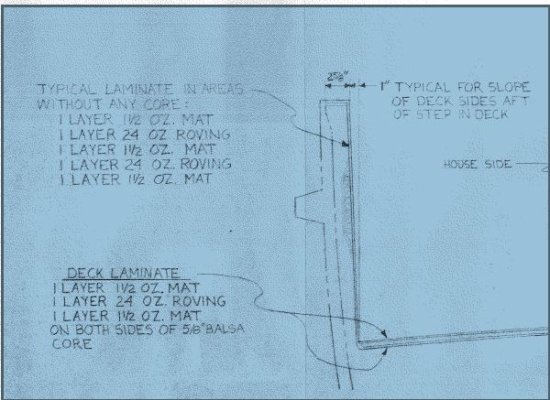

Thanks again to those who responded to my question pertaing to the KK42 Hull thickness. I require similar information on the thickness of the top layer of fiberglass on the side decks and the fore deck.

A vessel I am currently examining has had the fuel tanks replaced and the teaks removed from the fore and side decks. This reveals the top fiberglass deck. The screw holes were drilled out, filled with epoxy and an awl grip surface was put on. The seller indicates that the "wood turnings" from the drilling of the holes were dry. Although the deck looks good and feels strong to me, my surveyor maintains that questions remain about the integrity of the plywood core below. Certainly there are "voids" evident from sounding the decks.

How thick is the top fiberglass layer? How much strength did the teak deck contribute? Is the top layer of fiberglass of sufficient strength for the future "integrity" of the deck.

Jim

A vessel I am currently examining has had the fuel tanks replaced and the teaks removed from the fore and side decks. This reveals the top fiberglass deck. The screw holes were drilled out, filled with epoxy and an awl grip surface was put on. The seller indicates that the "wood turnings" from the drilling of the holes were dry. Although the deck looks good and feels strong to me, my surveyor maintains that questions remain about the integrity of the plywood core below. Certainly there are "voids" evident from sounding the decks.

How thick is the top fiberglass layer? How much strength did the teak deck contribute? Is the top layer of fiberglass of sufficient strength for the future "integrity" of the deck.

Jim

Last edited: