AusCan

Guru

- Joined

- Jul 15, 2012

- Messages

- 3,218

- Location

- Australia

- Vessel Name

- Kokanee

- Vessel Make

- Cuddles 30 Pilot House Motor Sailer

I have 3 on my 30 footer plus a couple spares.

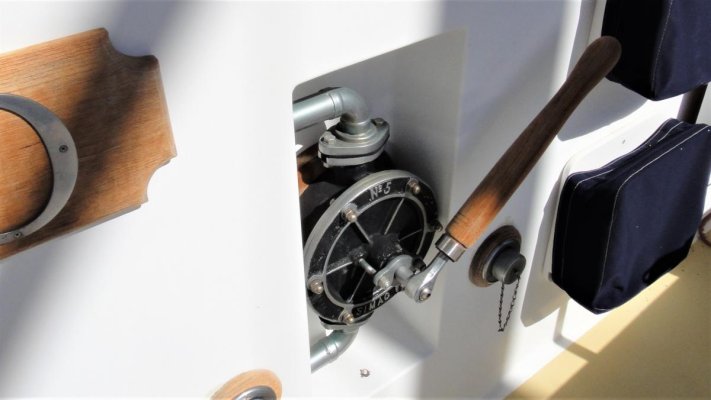

I also keep a variety of plugs, foam balls, tarps, bits of plywood, etc for dealing with a breach of the hull if necessary. I could never see the point of installing manual pumps. I would think that I'd be better off trying to slow the leak, rather than manually stroking a low volume pump if there ever was a hull breach.

Bridaus - I'm surprised you aren't aren't intimately familiar with your bilge pumps. Especially if it has been running daily. I'd be somewhat concerned about where the water is coming from.

I also keep a variety of plugs, foam balls, tarps, bits of plywood, etc for dealing with a breach of the hull if necessary. I could never see the point of installing manual pumps. I would think that I'd be better off trying to slow the leak, rather than manually stroking a low volume pump if there ever was a hull breach.

Bridaus - I'm surprised you aren't aren't intimately familiar with your bilge pumps. Especially if it has been running daily. I'd be somewhat concerned about where the water is coming from.