Bay Retriever

Senior Member

- Joined

- Oct 13, 2019

- Messages

- 150

- Location

- USA

- Vessel Name

- Bay Retriever

- Vessel Make

- 2004 Mainship 400

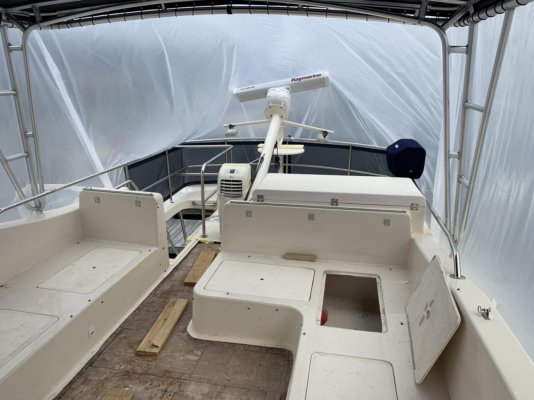

I recently purchased a 2004 MS 400 Trawler that I knew had soft core issues on the fly bridge deck. The flybridge deck is now exposed and the moisture seems to be coming in from somewhere in the front of the flybridge on the port side. Apparently, the rotten core goes underneath the seats.

Has anyone ever experienced moisture coming from the front of the flybridge? I have not yet seen the boat as I am traveling and will see if later this week to personally inspect and discuss with my Marina and Fiberglass techs the options and cost estimates for finishing the repair. The moisture has reportedly wicked from the port side of the helm station and runs front to back with the softest areas from just behind the Captain’s Chair towards the entry way at the top of the stairs.

Has anyone ever experienced moisture coming from the front of the flybridge? I have not yet seen the boat as I am traveling and will see if later this week to personally inspect and discuss with my Marina and Fiberglass techs the options and cost estimates for finishing the repair. The moisture has reportedly wicked from the port side of the helm station and runs front to back with the softest areas from just behind the Captain’s Chair towards the entry way at the top of the stairs.