jefndeb

Guru

Hello,

My latest project is interfacing the Yanmar 6LY2AN-STP analog engine data onto the NEMA 2K network via the Noland RS11 CanBus Adapter.

It takes in analog sensor signals that can be found on the rear side of the gauges. Trouble is, so far cannot locate any schematics or manuals/wiring specs for the displays.

I can see the Faria P/N on one of them, it shows Faria GF4017B, it is the Temp, Oil Press., volts and Fuel display. I cant see the P/N of the RPM display.

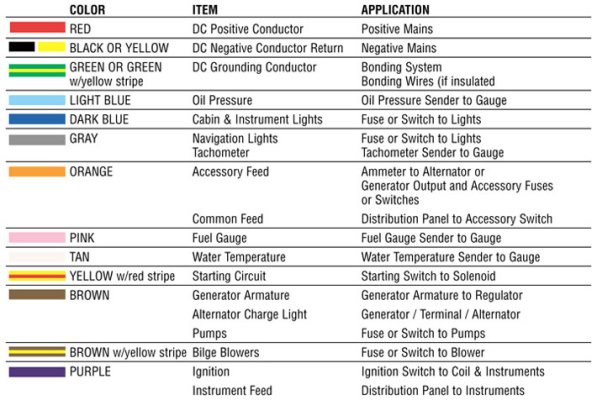

That P/N doesn't show up anywhere. The Mainship manual shows the wiring from the sensor to the display but its generic. I was hoping the wire colors would be reflected on the schematics but nope..

I placed a call to Faria tech support but I imagine they are out for the holidays..

Maybe someone out there has the data??

Jeff in Savannah

My latest project is interfacing the Yanmar 6LY2AN-STP analog engine data onto the NEMA 2K network via the Noland RS11 CanBus Adapter.

It takes in analog sensor signals that can be found on the rear side of the gauges. Trouble is, so far cannot locate any schematics or manuals/wiring specs for the displays.

I can see the Faria P/N on one of them, it shows Faria GF4017B, it is the Temp, Oil Press., volts and Fuel display. I cant see the P/N of the RPM display.

That P/N doesn't show up anywhere. The Mainship manual shows the wiring from the sensor to the display but its generic. I was hoping the wire colors would be reflected on the schematics but nope..

I placed a call to Faria tech support but I imagine they are out for the holidays..

Maybe someone out there has the data??

Jeff in Savannah