David,

Not wanting to hijack your thread, but based on Eric's last comment, I need to come in with a couple of related issues of my own.

I also seem to be suffering from a lot of Vibration of late. Actually, I am not sure on how long this has been an issue, but I think it has gotten worse since I purchased the boat a bit over 2 years ago. I do not recall anywhere near this much vibration during the sea-trial or on the homecoming trip from SF Bay up to the Delta, although I do make more of a point of running the engine harder at higher rpm to heat up the diesel and flush the exchanger before returning to the marina.

Let me start off with two points. I am of the same school as Eric with regard to the issue of running the diesel at higher rpm when cruising rather that lower because everything I have read and previous history of problems with this engine being run too slow would support this approach.

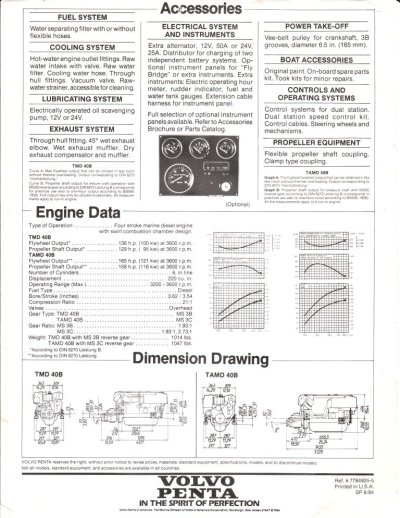

Point two, full disclosure, I am running a Turbo high-rev Volvo TAMD40B. (OK, go ahead and laugh...) The bottom line is that this engine tops out at 3600 rpm WOT. The Volvo seems to run well, no smoke, no oil burn, starts easy and has lots of power, no stalling or hesitation.(just hope I never need major parts)

I do not intend to operate at WOT, only to make sure on occasion that the engine and drive system are still capable of it.

My expectation is that at hull speed of about 7.5 kt that the engine would be running at 80% - 85% of its maximum. I typically cruise at 6 – 7 kt.

My thinking is thus; I know where the top of the throttle lever is, and that about matches the 3600 rpm on the lower station gauge. At this rpm WOT, I am pushing water like a bulldozer at around 9 kt. The Volvo is a powerful engine and has no problem spinning that 4-blade steep pitch prop – if I had trim tabs I could almost plane!

I think I am over-propped.

Eric, do you follow my thinking here and would it not make more sense to be cruising closer to 2800 - 3000 rpm, rather than the 2000 or so rpm that the boat appears to be propped to now? Depending on which previous survey I consult, the prop is either a 22" x 15, or 22 x 16. She is a 17,000 lb. boat. The engine is rated at ~ 155hp.

Now, back to the vibration issue. At my next haul-out I am thinking to have the prop pulled and hopefully cleaned up and balanced.( as well as service of the whole shaft) There is some debate as to whether this is possible, though being a great piece of bronze; I certainly would like to try with one of those PropScan shops.

In any case, even if I have to (heaven forbid) buy a new prop, I am seriously of a mind to have the pitch reduced enough to bump up my cruising rpm by at least 500 rpm.

I am in the process of getting educated on boat to prop engineering from some books I have and the Internet, but there is a lot of Experienced advice here and I thought it good to tap into it also.

Comments, criticisms, opinions?

Thanks.