Tony B

Guru

- Joined

- Jul 18, 2011

- Messages

- 1,251

- Location

- Cruising/Live-Aboard USA

- Vessel Name

- Serenity

- Vessel Make

- Mainship 36 Dual Cabin -1986

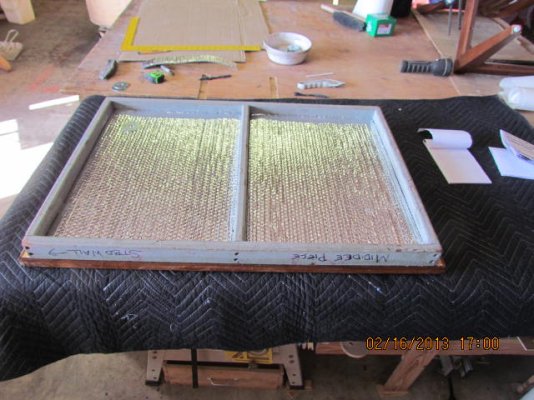

I recently finished my new floor boards which is actually the cabin sole directly over 2 Crusader 270 engines. There are 8 boards are approx. 2' X 3' each.

Sound deadening is not too much of a concern, however, some sort of fire retardant or fire proofing should be in stalled.

What is recommended for the sound and fire proofing insulation?

Sound deadening is not too much of a concern, however, some sort of fire retardant or fire proofing should be in stalled.

What is recommended for the sound and fire proofing insulation?