Can anyone make recommendations for a simple fuel use computer manufacturer for a twin 1100 hp diesel install (I know, I know, it's not a trawler but an interisland ferry project I'm involved with). Navman made one but discontinued. I can't seem to find any other reputable brands availablefor diesel.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fuel use computer advice

- Thread starter Nightcap

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

If you keep track well, after "dialing in" the flow scan will let you know if the gallons on the dock pump are really the full sized gallons you are paying for!.

Shoalwaters

Guru

- Joined

- Feb 24, 2008

- Messages

- 681

- Location

- St. Lucia, West Indies

- Vessel Name

- "Dragon Lady"

- Vessel Make

- DeFever 41

..................If they are electronic you can get that information from the ecm through the manufacturer.

I used to drive a boat with a pair of #3412 Cats equipped with digital instrument pannels. One of the display options was fuel flow. Pantropic (Caterpillar Miami) told me the engines were not actually measuring fuel flow, they were displaying the flow rate obtained by factory testing. I was never quite comfortable with that. How do other engine manufacturers measure fuel flow?

Vyndance

Senior Member

I used to drive a boat with a pair of #3412 Cats equipped with digital instrument pannels. One of the display options was fuel flow. Pantropic (Caterpillar Miami) told me the engines were not actually measuring fuel flow, they were displaying the flow rate obtained by factory testing. I was never quite comfortable with that. How do other engine manufacturers measure fuel flow?

I didn't know that was how it was done but the manufacturer knows exactly how many pounds per hour the motor will burn at any given RPM. It's called Brake Specific Fuel Consumption(I think!) and is for some reason a tightly guarded secret. If the motor is operating correctly, and the operator would know if it wasn't, it would be spot on. They are probably all the same.

theran5317

Veteran Member

I didn't know that was how it was done but the manufacturer knows exactly how many pounds per hour the motor will burn at any given RPM. It's called Brake Specific Fuel Consumption(I think!) and is for some reason a tightly guarded secret. If the motor is operating correctly, and the operator would know if it wasn't, it would be spot on. They are probably all the same.

This couldn't be strictly by RPM? Doesn't a governor control the fuel flow to maintain a given RPM? The fuel flow would then be based on the engine load. The governor would be supplying more/less fuel to maintain the selected RPM setpoint based on the throttle positon.

For propulsion in a boat, the RPM might statement might be true, but for many other applications such as generators, this would not be the case.

RickB

Guru

- Joined

- Oct 20, 2007

- Messages

- 3,804

- Vessel Make

- CHB 48 Zodiac YL 4.2

The fuel flow would then be based on the engine load. The governor would be supplying more/less fuel to maintain the selected RPM setpoint based on the throttle positon.

That is correct.

For propulsion in a boat, the RPM might statement might be true ...

Only in a very general way. The propeller curve is a calculated load, the actual load will vary considerably with engine condition, wind, waves, loading, rudder angle, trim, air temperature, fuel temperature, hull fouling, propeller fouling, the solar wind, almost any and everything will alter the figure.

The only way to know actual fuel burn is to measure it.

millennium

Veteran Member

The Floscan instruments need to be calibrated after the installation?

I can imagine that would be a very inexact science.

I can imagine that would be a very inexact science.

av8r

Senior Member

Yes they have to be calibrated but the initial settings will probably be pretty close. After that it is a process of matching the fuel consumed to the gage reading. Refuel to a known point and adjust the gage reading to match.

Peregrinator

Member

Another option I an looking at for my old cat 3208s is this:

Maretron : Marine Electronic Instruments

It apears to be a simpler install on the plumbing side, not sure about their claim of being cheaper.

I will be interested in seeing what your final system looks like.

Maretron : Marine Electronic Instruments

It apears to be a simpler install on the plumbing side, not sure about their claim of being cheaper.

I will be interested in seeing what your final system looks like.

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

I can imagine that would be a very inexact science.

Not at all, and couldnt be simpler.

After fueling (to the brim) you note the gallons paid for.

Then look at the Flowscan measured gallons used .

If they disagree a tiny dial will reset the gallons used to closely match the fill amount.

You then reset , and you are done.

For greater accuracy , dont reset and simply allow the meter to keep counting as you log each fuel,fill.

Eventually you will fill to the brim again and adjusting for 1200gal will give more accuracy than a couple of hundred. After a while its a big game , till it ends , when the fill and measured match.

Well under 1% accuracy can be got with patience.

We fill say 160 gal in two tanks and the gauge shows 158 burned , no big deal to me.

Not at all, and couldnt be simpler.

After fueling (to the brim) you note the gallons paid for.

Then look at the Flowscan measured gallons used .

If they disagree a tiny dial will reset the gallons used to closely match the fill amount.

You then reset , and you are done.

For greater accuracy , dont reset and simply allow the meter to keep counting as you log each fuel,fill.

Eventually you will fill to the brim again and adjusting for 1200gal will give more accuracy than a couple of hundred. After a while its a big game , till it ends , when the fill and measured match.

Well under 1% accuracy can be got with patience.

We fill say 160 gal in two tanks and the gauge shows 158 burned , no big deal to me.

Last edited:

Shoalwaters

Guru

- Joined

- Feb 24, 2008

- Messages

- 681

- Location

- St. Lucia, West Indies

- Vessel Name

- "Dragon Lady"

- Vessel Make

- DeFever 41

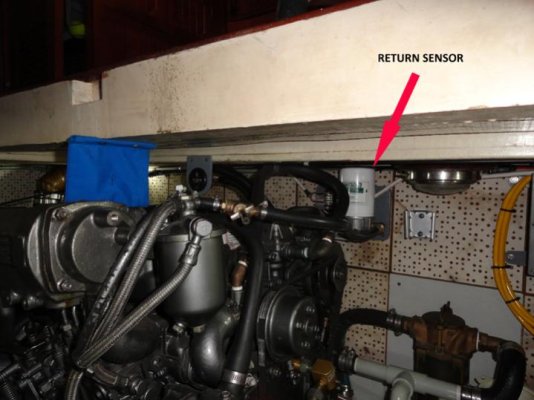

Those considering Floscan(s) may find the following of use as I recently installed a Floscan #6510 on one of my Yanmar 4LH-DTE's. These units calculate fuel consumption by measuring the volume of fuel supplied to the engine and subtracting the volume returned to the tank. Flow is displayed on an analog gauge; there is also a totalizer. Step one of the calibration procedure is to set the No Load Idle Consumption (NLIC). This is selected from a chart of engine horsepower - mine is supposed to be 0.2-0.6 gals/hr. All well and good if the meter reads this figure on initial start-up (mine did - around 0.4). If it doesn't, then adjustments are made to the meter so that it does. Floscan say this is to "...calibrate out the errors induced by pulsations and fluctuations". Step two is to verify the totalizer by the procedure av8r and FF describe. In both cases adjustments are made to dip-switches on the back of the analog meter. The totalizer requires a constant 12 volt supply; any interuption and it resets to zero. I find this to be something of a PITA as I shut down all my electrics except the bilge pump circuit when I leave the boat. At over $600 per unit, I feel Floscan could have included battery backup for the totalizer. I mounted the meter in a plastic box to accomodate the power-on light, fuse and reset button. Only the meter is supplied by Floscan. The things like inverted oil filters are pulsation dampers. The eagle-eyed will note that the primer bulb next to the supply sensor was relocated after the first pic was taken.

Attachments

JD

Guru

Another option I an looking at for my old cat 3208s is this:

Maretron : Marine Electronic Instruments

It apears to be a simpler install on the plumbing side, not sure about their claim of being cheaper.

I will be interested in seeing what your final system looks like.

Looks like the sensors are $420 each and you need two for a single engine boat, the Flow monitor is $325 so that's $1,165 for the fuel system and then you need a monitor with NEMA 2000 capabilities. So I'm guessing that an E80 or newer Raymarine or 3010 or newer Garmin. Otherwise a new monitor.

So $1,200 if your chart plotter works or more if it doesn't.

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

Looks like the sensors are $420 each and you need two for a single engine boat, the Flow monitor is $325 so that's $1,165 for the fuel system and then you need a monitor with NEMA 2000 capabilities..

The Coot's builder charged $1300 for two FlowScan sensors and a monitor, installed, in 2010.

millennium

Veteran Member

Thanks Shoalwaters.

I think I may be asking Santa for a pair of Floscans(twin Yanmars), although I know one would do the job.

The the 0 to 10 gph scale work with the LH's, I would think they would burn more then 10 gph at high power settings.

I think I may be asking Santa for a pair of Floscans(twin Yanmars), although I know one would do the job.

The the 0 to 10 gph scale work with the LH's, I would think they would burn more then 10 gph at high power settings.

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

FloScan offers monitors with different ranges.

We have Flow Scan which is a nice tool but look our how you are going to use it and how it is plumbed into your fuel system. When we bought Hobo we were trying to figure out the best speed/rpms vs gph. We were a week into the "new" boat and I started the generator and WTF! The generator was plumbed into the Flow Scan loop. To keep a handle on fuel remaining in the tanks, more sensors were needed for the generator, 2 separate systems as Flow Scan explained to us. The FL 135 returns very little to the tanks vs the Northern Lights 8 Kw gen set that returns a lot and the consumption numbers are different.

Last edited:

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

"The generator was plumbed into the Flow Scan loop."

Is it too late to fire bomb the boat assembler?

Is it too late to fire bomb the boat assembler?

Sorry I bailed out of this discussion, an unexpected trip away. We've bitten the bullet and ordered the Flonet series for 2x twin engine boats. Not cheap but payback will be under 6 months if we can achieve 5% fuel savings by operational changes. We went with the higher end model as it has a data logging function and the ability to query realtime data via smartphone. If we're going to make changes to operational speeds etc we needed to know the skippers were implementing them properly.

Similar threads

- Replies

- 14

- Views

- 1K

- Replies

- 26

- Views

- 3K