Quick question, the gibble bearing on our 30' Sundowner was replaced in 2015, yesterday on a 5 hr. cruise we took a temperature with a heat gun. The shaft was 98° on the forward side of the bearing, the stern side was 103°, the housing of the bearing itself was 122°, does that fall within "normal"?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gibble bearing

- Thread starter Turner

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

C lectric

Guru

What is a gibble bearing? Never heard that term except to mean something wrecked or damaged. Hope you haven't gibbled your shaft.

Do you mean the prop shaft stuffing box? Those temps sound alright to me for the stuffing/packing box. As a general guidline if you can hold your hand on the metal part of the stuffing box then the temp is ok.

Do you mean the prop shaft stuffing box? Those temps sound alright to me for the stuffing/packing box. As a general guidline if you can hold your hand on the metal part of the stuffing box then the temp is ok.

My understanding is the gibble bearing is the bearing that supports the middle of the shaft inside the boat the stuffing housing measured 86°.What is a gibble bearing? Never heard that term except to mean something wrecked or damaged. Hope you haven't gibbled your shaft.

Do you mean the prop shaft stuffing box? Those temps sound alright to me for the stuffing/packing box. As a general guidline if you can hold your hand on the metal part of the stuffing box then the temp is ok.

Madhatter53

Veteran Member

Gimble bearing.

No such thing as a gibble or gimble bearing.

A "gimbal" is a bearing that allows something to tilt or swing to stay level such as some a gimballed stove, some gimballed compass bearings or an i/o drive to tilt etc.

I can't see why you would have one of these on your shaft unless your shaft was in two pieces and it was somehow tied in with a universal joint ... something like the old "dis-pro (disappearing propeller) boats

I suspect you mean a pillow block bearing but given your limited description I wouldn't bet on that because I've never seen a Sundowner 30 with a pillow block bearing either as thee shaft is too short to need one.

I suggest you Google these terms and let us know what you are talking about.

A "gimbal" is a bearing that allows something to tilt or swing to stay level such as some a gimballed stove, some gimballed compass bearings or an i/o drive to tilt etc.

I can't see why you would have one of these on your shaft unless your shaft was in two pieces and it was somehow tied in with a universal joint ... something like the old "dis-pro (disappearing propeller) boats

I suspect you mean a pillow block bearing but given your limited description I wouldn't bet on that because I've never seen a Sundowner 30 with a pillow block bearing either as thee shaft is too short to need one.

I suggest you Google these terms and let us know what you are talking about.

Last edited:

Sounds like a Sundancer with an IO and a gimbal bearing which makes sense.

Don't think so. An i/o does not have a stuffing box and no way to feel the temp of the shaft.

Lepke

Guru

- Joined

- Jun 19, 2016

- Messages

- 3,033

- Location

- US

- Vessel Name

- Charlie Harper

- Vessel Make

- Wheeler Shipyard 83'

The temps are well within a safe temperature range. As long as the bearing has proper grease.

If you want to lower the temps, try this grease from Archoil. They are leaders in nano lubrication. Your bearing will spin easier and cooler. I use most of their products.

https://www.archoil.com/collections/products/products/ar8000-grease?variant=12421963350098

If you want to lower the temps, try this grease from Archoil. They are leaders in nano lubrication. Your bearing will spin easier and cooler. I use most of their products.

https://www.archoil.com/collections/products/products/ar8000-grease?variant=12421963350098

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,273

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

Agree gimble bearings are in stern drives. Maybe a photo of the bearing you are talking about.

fractalphreak

Senior Member

- Joined

- Jun 23, 2018

- Messages

- 318

- Location

- United States

- Vessel Name

- Northwest Dream

- Vessel Make

- Davis Vashon 42 Trawler (Defever design)

Turner,

Found this in a google search...

https://www.sailangle.com/group-forum/topic/id/1453/page/1/sort/desc

Its an old discussion about a pillow block bearing on Sundowner 30's and whether it is needed due to the length of unsupported shaft. Don't know whether I'd recommend removing it, but it looks like others have had concerns about them.

Found this in a google search...

https://www.sailangle.com/group-forum/topic/id/1453/page/1/sort/desc

Its an old discussion about a pillow block bearing on Sundowner 30's and whether it is needed due to the length of unsupported shaft. Don't know whether I'd recommend removing it, but it looks like others have had concerns about them.

Good suggestion and reassuring comment on temperature. The temps didn't seem to be bad, just wanted thoughts from the forum. As a group the TF people provide so much knowledge to each other. Thanks.The temps are well within a safe temperature range. As long as the bearing has proper grease.

If you want to lower the temps, try this grease from Archoil. They are leaders in nano lubrication. Your bearing will spin easier and cooler. I use most of their products.

https://www.archoil.com/collections/products/products/ar8000-grease?variant=12421963350098

jleonard

Guru

- Joined

- Jun 25, 2008

- Messages

- 5,061

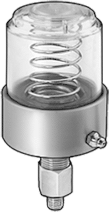

Put an automatic grease system on like this (McMaster Carr) and you won't have to worry about it.

I put one of these on my "ex" an old 34 Mainship as the fitting was hard to get to. I used a length of hydraulic hose to get it to a handy location.

I also had on of those go bad...it squeaked (when I went into reverse) and rumbled. If it's quiet don't worry about it.

I put one of these on my "ex" an old 34 Mainship as the fitting was hard to get to. I used a length of hydraulic hose to get it to a handy location.

I also had on of those go bad...it squeaked (when I went into reverse) and rumbled. If it's quiet don't worry about it.

Attachments

Woodland Hills

Guru

If the engine is new and the bushing was not hot prior to the new installation, perhaps there is an alignment issue? When the work was performed was alignment checked on the hard or in the water? Having the hull supported by blocks in a few locations is very different from being supported by water.

Last edited:

C lectric

Guru

Late I see.

My BIL had a 30 Sundowner and that boat had the bearing in the picture.

I called it an intermediate bearing although the type was a pillow block.

We would grease it once a year with a waterproof lithium based grease.

As discussed the temps are OK, Good.

My BIL had a 30 Sundowner and that boat had the bearing in the picture.

I called it an intermediate bearing although the type was a pillow block.

We would grease it once a year with a waterproof lithium based grease.

As discussed the temps are OK, Good.

deblen

Veteran Member

- Joined

- Jun 19, 2018

- Messages

- 65

- Location

- Bay of Fundy-Canada

- Vessel Name

- Puffin II

- Vessel Make

- Mascot 28 PH Motorsailer

Here's a picture of the bearing I am referring to located 1/2 way between engine and the hacking housingView attachment 83966

That appears to be a "self aligning pillow block steady bearing".

The self aligning happens because the actual ball/roller cage can gimbal within the cast iron pillow,allowing the ball/roller cage to automatically align squarely with the shaft longitudinally.

There are 4 bolt/nut jacks to allow the whole assembly to be raised/lowered/moved sideways to align with the shaft centerline.

From your description,I don't believe you have any problem with it at present.Grease it once or twice a year. / Len

link to an example of the older style non-self aligning babbit steady bearing

https://www.marinesource.ca/products/steady-bearing-1-1-2

Really appreciate all the info you provided! The longer I'm on this site the more I learn and the more I realize how much more there is to learn, thanks.That appears to be a "self aligning pillow block steady bearing".

The self aligning happens because the actual ball/roller cage can gimbal within the cast iron pillow,allowing the ball/roller cage to automatically align squarely with the shaft longitudinally.

There are 4 bolt/nut jacks to allow the whole assembly to be raised/lowered/moved sideways to align with the shaft centerline.

From your description,I don't believe you have any problem with it at present.Grease it once or twice a year. / Len

link to an example of the older style non-self aligning babbit steady bearing

https://www.marinesource.ca/products/steady-bearing-1-1-2

Lou_tribal

Guru

I have something similar aboard (pillow block bearing) between packing gland and an universal joint on engine side. Mine run between 120 and 140 F. I grease it once a year before going back in the water.

L

L

deblen

Veteran Member

- Joined

- Jun 19, 2018

- Messages

- 65

- Location

- Bay of Fundy-Canada

- Vessel Name

- Puffin II

- Vessel Make

- Mascot 28 PH Motorsailer

I have something similar aboard (pillow block bearing) between packing gland and an universal joint on engine side. Mine run between 120 and 140 F. I grease it once a year before going back in the water.

L

You probably have a thrust bearing mounted to the hull also. Proper gear IMHO! / Len

Welcome to Aquadrive

Lou_tribal

Guru

You probably have a thrust bearing mounted to the hull also. Proper gear IMHO! / Len

Welcome to Aquadrive

Not exactly an aquadrive, here is my setup:

On the right the pillow bearing, on the left the dual universal joint (cardan).

L

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,865

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

My Bruno & Stillman has a carrier bearing, intermediate bearing, or whatever you want to call it. It is a pillow block style, same as what is pictured in this thread. The bearing keeps the shaft from whipping (vibration from deflection at higher RPM). As mentioned, it does need to be greased and checked for wear. Basically, you need to try to move the shaft shaft side to side, or up and down to check for wear. Also turn the shaft to check for smoothness in the rotation of the bearing. As a cautionary note, the one in my charter boat doesn't have a long life expectancy. Ideally it should have roller bearings as opposed to ball bearings. Due to the location limitations, a roller bearing pillow block won't fit. So, I've replaced it a number of times. This is unusual and likely not a problem you should have.

Ted

Ted

Simi 60

Guru

- Joined

- Jul 1, 2016

- Messages

- 5,482

- Location

- Australia

- Vessel Make

- Milkraft 60 converted timber prawn trawler

Put an automatic grease system on like this (McMaster Carr) and you won't have to worry about it.

.

You will when it runs out of grease.

Personally, I prefer to manually grease mine as it gives me a reason to look down that hole sooner rather than later and see if there are any issues.

I give mine a few pumps every couple of months.

Grease is cheap, bearings are not.

Last edited:

jleonard

Guru

- Joined

- Jun 25, 2008

- Messages

- 5,061

You will when it runs out of grease.

Personally, I prefer to manually grease mine as it gives me a reason to look down that hole sooner rather than later and see if there are any issues.

I give mine a few pumps every couple of months.

Grease is cheap, bearings are not.

Mine still had grease in it after 9 years.

I also had made a plexiglass window over the bearing so it was easy to inspect.

The other advantage is that the spring pressure makes sure moisture can't get in. The same way bearing buddies work on a trailer.

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

If someone has an Aquadrive system , the units last longest with minor out of alignment , as it helps lubricate the units.

Don't ask how I learned this!

Don't ask how I learned this!

Riverguy

Senior Member

- Joined

- Feb 17, 2013

- Messages

- 285

- Location

- USA

- Vessel Name

- Serendipitous

- Vessel Make

- Mainship 390, Bayliner 3258, Bayliner 4788

Bearing heat bears further investigation...

To me, the biggest clue here is that "the bearing was replaced in 2015". The question then is why was it replaced?

It seems to me that if the prop shaft and engine alignment are correct, this bearing should have very little load on it, and (if properly lubricated) there should not be enough friction to produce much heat.

The missing part of this equation is, what is the ambient temperature at the location of this bearing?

Assuming ~70 degrees ambient, it takes a VERY great deal of heat to raise the temperature of your shaft ~ 30 degrees, and raise the temperature of the housing ~50 degrees. All of that heat is coming from friction. Remember that rise in Temperature = Heat x Mass.

http://hyperphysics.phy-astr.gsu.edu/hbase/thermo/spht.html

So...given the history of failure of this bearing, I would investigate this further. I think that both the shaft and the housing should be running pretty close to the ambient temperature. Either the bearing is running too dry, or it is running under too heavy a load, or probably both. Don't let the (relatively) low temperatures you are measuring fool you. The shaft is acting as a massive heat-sink and it is absorbing and carrying away a LOT of heat.

My guess is you are going to find some shaft misalignment somewhere...

Good luck!

To me, the biggest clue here is that "the bearing was replaced in 2015". The question then is why was it replaced?

It seems to me that if the prop shaft and engine alignment are correct, this bearing should have very little load on it, and (if properly lubricated) there should not be enough friction to produce much heat.

The missing part of this equation is, what is the ambient temperature at the location of this bearing?

Assuming ~70 degrees ambient, it takes a VERY great deal of heat to raise the temperature of your shaft ~ 30 degrees, and raise the temperature of the housing ~50 degrees. All of that heat is coming from friction. Remember that rise in Temperature = Heat x Mass.

http://hyperphysics.phy-astr.gsu.edu/hbase/thermo/spht.html

So...given the history of failure of this bearing, I would investigate this further. I think that both the shaft and the housing should be running pretty close to the ambient temperature. Either the bearing is running too dry, or it is running under too heavy a load, or probably both. Don't let the (relatively) low temperatures you are measuring fool you. The shaft is acting as a massive heat-sink and it is absorbing and carrying away a LOT of heat.

My guess is you are going to find some shaft misalignment somewhere...

Good luck!

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

"So...given the history of failure of this bearing, I would investigate this further."

Best guess it was under water.

Best guess it was under water.

Similar threads

- Replies

- 15

- Views

- 3K