toocoys

Guru

Our holding tank is approx 30 gallons or so, and its aluminum. It's nearing the end of its life and we do plan to replace it with a polytank, but we'd like to squeeze another year of life out of it, or at least have it carry us until next season.

Currently the inlets look like this crude drawing. The parts where the hoses connect are severely corroded and I cannot get a good seal to keep it from leaking.

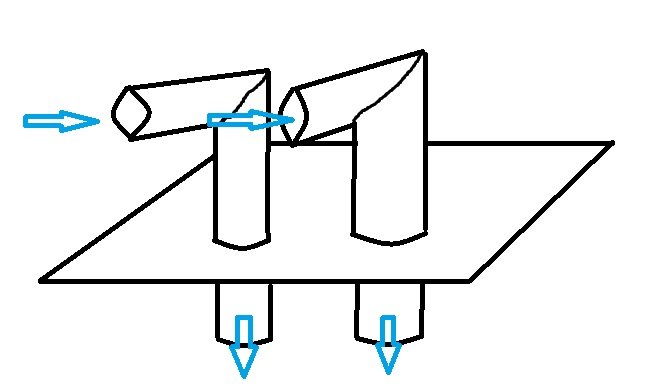

What I would like to do is cut the current inlets out, and replace it with a fabricated part like this. Just two aluminum inlets, welded to a plate, that I can then epoxy over the hole that I cut out.

What I'm wondering is if there is a way to do this in PVC, or some plastic material instead of having to track down an aluminum fabricator?

Any suggestions? (And yes I know that doing this is only delaying the inevitable, but as I said we're trying to squeeze a little more life out of the tank before we ultimately replace it.)

Currently the inlets look like this crude drawing. The parts where the hoses connect are severely corroded and I cannot get a good seal to keep it from leaking.

What I would like to do is cut the current inlets out, and replace it with a fabricated part like this. Just two aluminum inlets, welded to a plate, that I can then epoxy over the hole that I cut out.

What I'm wondering is if there is a way to do this in PVC, or some plastic material instead of having to track down an aluminum fabricator?

Any suggestions? (And yes I know that doing this is only delaying the inevitable, but as I said we're trying to squeeze a little more life out of the tank before we ultimately replace it.)