FBoykin

Senior Member

- Joined

- Feb 13, 2014

- Messages

- 165

- Vessel Name

- Hannah Jane

- Vessel Make

- 2000 Grand Banks 42 Classic

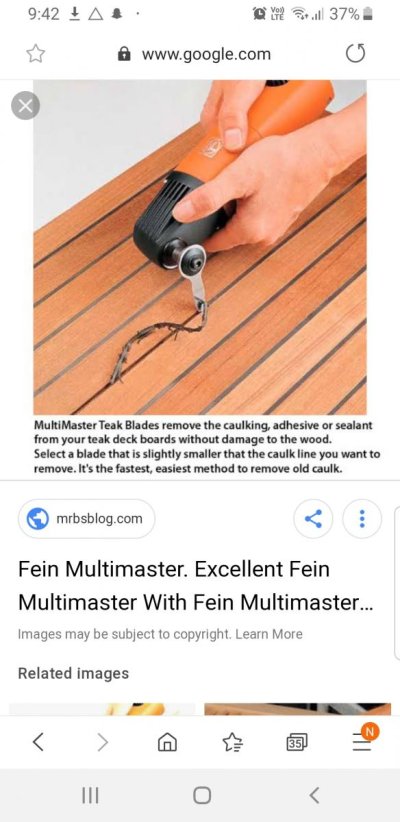

That Veritas plane looks interesting! I tried out my Makita 3 1/2" saw on my bow locker hatch. It did ok, but there was still plenty of handwork afterwards and I was always on edge that I was going to mis-cut my teak. So I did the smaller of my 2 lazarette hatches by hand with a Fein tool, Teak Decking Systems reef hook & sanding block plus MM size hand chisels and a nice English plow plane I found on Ebay. It turned out very well, but took more time than expected.

I sent mplangley a message with questions. Mainly how well di it work and what was his preferred method of use. His plane looks like a very, very useful tool! Unfortunately, tool is out of stock until late April...

I sent mplangley a message with questions. Mainly how well di it work and what was his preferred method of use. His plane looks like a very, very useful tool! Unfortunately, tool is out of stock until late April...